3

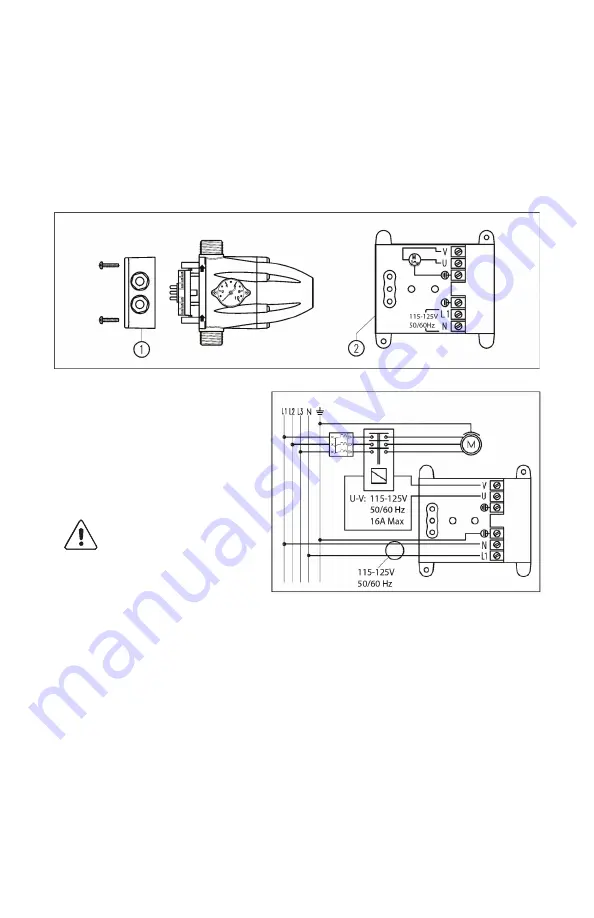

Electrical Connection

Ensure the voltage supply corresponds to the rated voltage. Remove

the cover (faceplate) from the electronic board and make the elec-

trical connection according to the instructions shown inside. This

controller can also be used with a single-phase pump with electrical

demand greater than 16A, or a three-phase pump, using an auxiliary

remote control switch (115V coil). In this case, the electrical connec-

tions must be made as shown in the diagram.

WARNING:

Power supply

voltages other than those

specified or improper con

-

nections can permanently

damage the electronic

components and will void

the warranty.

SOOW or H07RN-F

type cables (.35-0.5in/

9-12mm O.D.) must be

used in order to ensure

IP65 protection.

4. STARTING AND OPERATING

Start Up

1. Check that the pump is primed properly, then partially open a

faucet or valve in the user circuit.

2. Turn on power to the controller; the power LED will light up

(Power).

3. While the pump is running, the corresponding LED (On) will

remain illuminated.

4. Close the open faucet or valve. After 10- 12 seconds the pump

will stop running, but the power supply LED (Power) will remain

lit. Improper priming will cause malfunctions to occur.