6

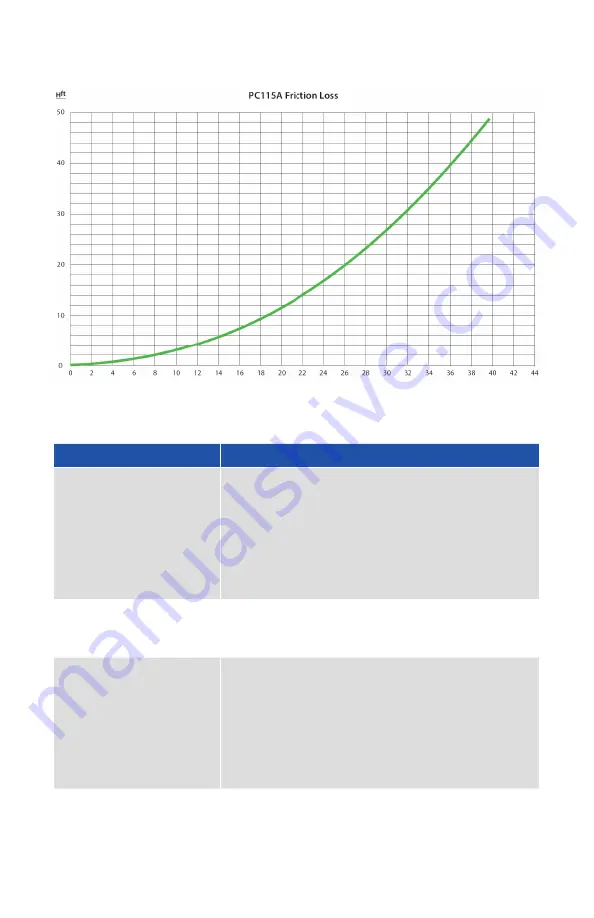

6. CONTROLLER FRICTION LOSS

7. TROUBLESHOOTING

Issue

Solution

The pump does not

start

• Try pressing the manual reset button.

• Check the power supply. The Power LED

must be illuminated.

• Electronic board malfunction: disconnect

the pump from the electrical mains and

reconnect it; the pump should start, if it

does not replace the controller board.

The pump keeps

stopping and starting

• There is a small leak in the delivery pipe-

line: check for any leaking taps or running

toilets.

The pump does not

stop

• Water loss exceeding 0.8 GPM. Make

sure that all the taps along the pipeline

are closed and that there are no leaks.

• The electrical connection is incorrect:

refer to the instructions, page 3.

• Electronic board malfunction: replace the

electronic board.