2

(A)

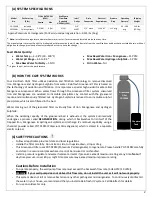

SYSTEM SPECIFICATIONS

Model

No.

Pot Perm Jug

(5 lbs)

FLOW RATE GPM

(LPM)

Well Pump

Flow Rate

Required

US GPM (LPM)

Inlet /

Outlet

Drain

Connection

Electrical

Requirement

Pressure

Drop

Operating

Pressure*

Shipping

Weight

Service

Max

CGFE948

Included

2.2 (8.3)

5 (19)

5 (19)

3/4"

MNPT

1/2" Hose

110V AC

< 15 psig

30 – 100

psig

140 lbs

(63.5 Kg)

CGFE948L

Sold separately

Approx Potassium Permanganate (Pot-Perm) used per regeneration : 0.125 lbs (56 g)

*

Note:

Install pressure regulator and water hammer arrestor if pressure exceeds rated pressure at any time.

The manufacturer reserves the right to make product improvements which may deviate from the specifications and descriptions stated herein, without

obligation to change previously manufactured products or to note the change.

Feed Water Quality:

Water Temp –

4

-

38°C (39 - 100°F)

Water pH Range –

6.5 to 8.5*

Max Raw Water Turbidity –

5 NTU

Max Raw Water Iron + Manganese –

15 PPM

Max Raw Water Hydrogen Sulphide –

5 PPM

Oil in Water –

Nil

* -

higher the pH, better the performance

(B)

HOW THE CGFE SYSTEM WORKS

Your Rainfresh CGFE filter utilizes oxidation and filtration technology to remove dissolved

Iron, Manganese and Hydrogen Sulphide from water. Rainfresh Greensand Filter is based on

the technology of oxidation and filtration. It incorporates a special high-oxidant media called

Manganese Greensand. When water flows through the Greensand filter system, dissolved

Iron and Manganese are oxidized to insoluble precipitates by contact with the greensand

media, and simultaneously filtered out. Hydrogen Sulphide is reduced to an insoluble sulphur

precipitate, which is also filtered in the bed.

Water coming out of the greensand filter is virtually free of Iron, Manganese and Hydrogen

Sulphide.

When the oxidizing capacity of the greensand bed is exhausted, the system automatically

undergoes a process called

REGENERATION

, during which it backwashes to rid itself of the

trapped Iron, Manganese & Hydrogen Sulphide and recharge it’s removal capability using a

chemical powder called POT PERM (Potassium Permanganate) which is stored in a separate

small container.

(C)

SAFETY PRECAUTIONS

-

Follow all applicable province/state and local regulations.

-

Handle the filter carefully. Do not lie on side, turn upside down, drop or drag.

-

This Greensand Filter uses POT-PERM (Potassium Permanganate) to regenerate. Please handle POT-PERM carefully

and store in a secure cool place where it cannot be misused or mishandled.

-

Install a pressure regulator and water hammer arrestor if pressure exceeds maximum rating at any time.

Note:

If

daytime pressure is over 80 psi, night time pressure may exceed maximum pressure rating.

Cautions Before Installation

-

To operate properly, the well pump flow rate must exceed the backwash flow rate (5 US GPM (19 LPM)).

-

Warning:

If your well pump does not deliver this flow rate, do not install the unit as it will not work properly

.

-

This system does not kill or remove bacteria or any other pathogenic microorganisms. To continuously disinfect all

the water in your house, we recommend that you install a Rainfresh UV system. Call Rainfresh for details.

-

For use on cold water only.

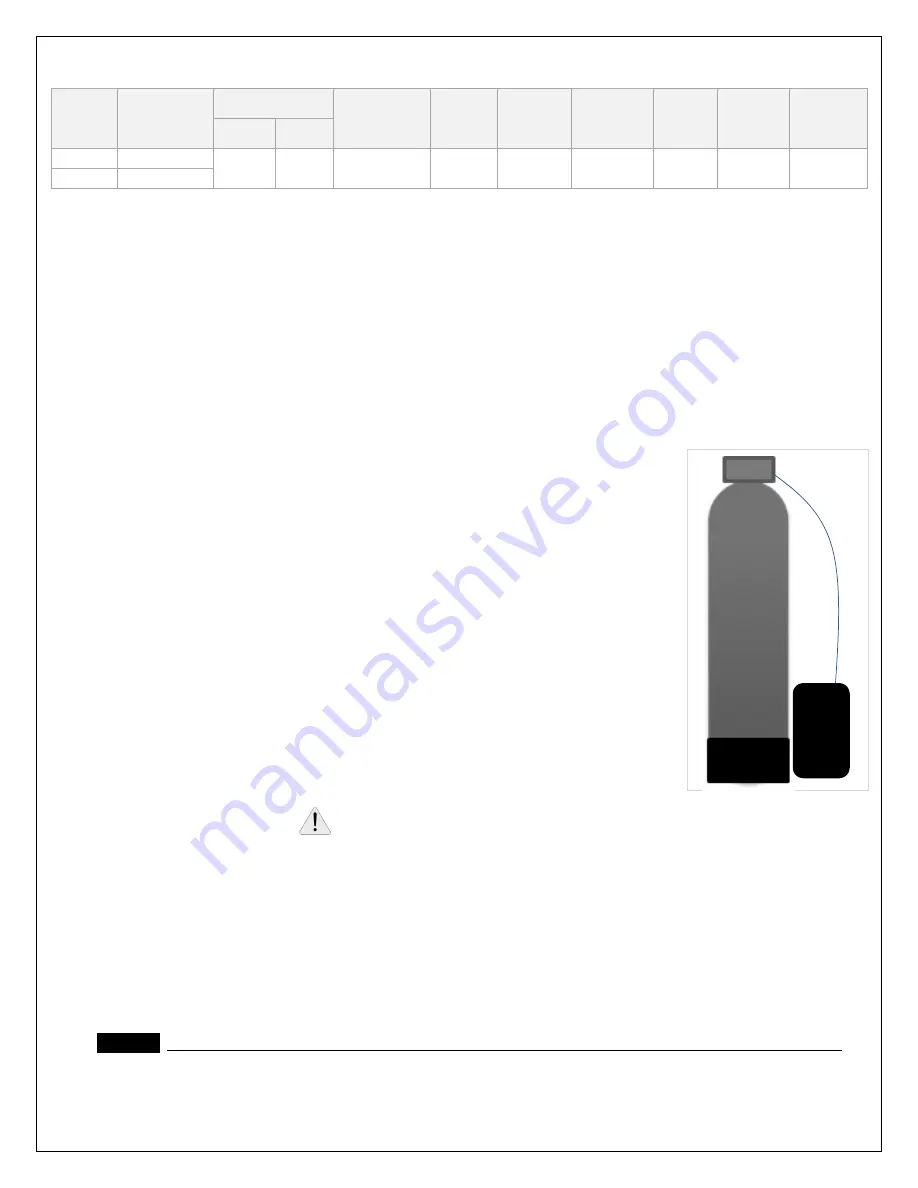

Greensand

Filter

CGFE948

Chemical

Tank

Summary of Contents for CGFE948

Page 13: ...13 PARTS LIST...