4

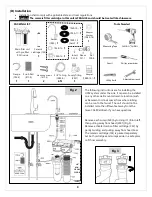

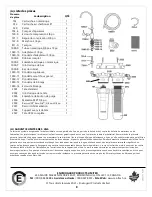

Step 1: Mounting the Faucet

Faucet may be installed in existing hole in sink if available or in counter top.

Note:

The faucet may also be installed in the sink sprayer hole if available.

1.

Position faucet on counter top beside sink in desired position. Ensure that swivel spout will

extend over sink and that there is room under the counter for faucet shank and to tighten

nuts.

2.

Mark the location and drill a ½” hole (Fig 2). Protect your laminate counter top by applying

a layer of masking tape and use a sharp drill bit.

Caution:

For granite or other stone

countertops, hole should be drilled only by a professional. Do not attempt to do this

yourself to prevent breakage.

3.

Insert faucet shank through escutcheon washer (1050-10), and then through counter top

(See Fig 4). From under the sink, install 1050-11 large washer, plastic washer (1050-12), metal lock washer (1050-13)

and locking nut (1050-14) as shown in fig 3. Using a wrench, tighten locking nut securely while someone holds the

faucet body so it does not turn. Place adaptor washer (1040-16) inside 3/8” adapter (1040-15) (Fig 4) and tighten

adaptor securely on to the faucet shank with a wrench.

Note

:

Do not use any thread sealant or tape on the faucet

shank.

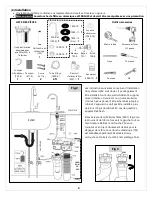

Step 2: Mounting the Unit

1.

Locate best position for mounting unit undersink near faucet. Mark mounting

bracket screw locations using mounting bracket (2565) as a template (Fig 5).

Use a level to align holes parallel to cabinet base.

Note:

LEAVE

MINIMUM OF

18 INCHES

CLEARANCE from the top edge of the bracket to the cabinet floor.

THE HIGHER AND CLOSER TO THE FRONT YOU MOUNT THE UNIT THE

BETTER FOR REGULAR MAINTENANCE.

2.

Partially screw the 2 mounting bracket screws (1011-0) into screw locations. Install mounting bracket and head

assembly over screw heads. Use a level to make sure bracket is level and tighten screws.

Note:

If wall is too thin to

accept screws then use round head nuts and bolts (not supplied) to mount bracket.

Step 3: Connecting the faucet

Measure and cut a length from plastic tubing (1009-0) to

connect faucet to the OUTLET fitting (2553). Make sure to

leave enough tube for connecting supply valve to INLET.

Note:

Use only a sharp knife to cut the tube straight

(Fig 6). Using a saw or cutting the tube at an angle can

cause the fitting to leak.

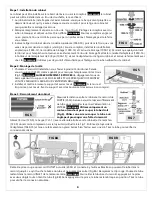

Slide compression nut (720-0) and compression sleeve (721-1) (with narrow end towards faucet)

onto tube and put tube insert (722-0) into tube as shown in Fig 7. Push tube into end of adaptor

(1040-15) and hold firmly in place. Now tighten nut securely with a wrench. Pull tube to check secure connection.

Remove the red clip on the OUTLET Acculink

TM

fitting (2553) and connect the other end of tubing to it by pushing the tube

into the fitting until it touches the tube stop and cannot go in any further (Fig 8A). Replace lock ring. Push the remaining

tube into the INLET fitting the same way.

Note:

To remove tubing from the fitting, press the collet in with two fingers while

pulling tube out (Fig 8B). Without pressing the collet, the tubing will stay locked in position. Pull tube to check secure

connection.

3

FIG 5

FIG 8A

FIG 8B

FIG 6

FIG 4

FIG 7