N-Series

3D Printer

/ Quick Start Guide

B

Hardware Installation

(continued)

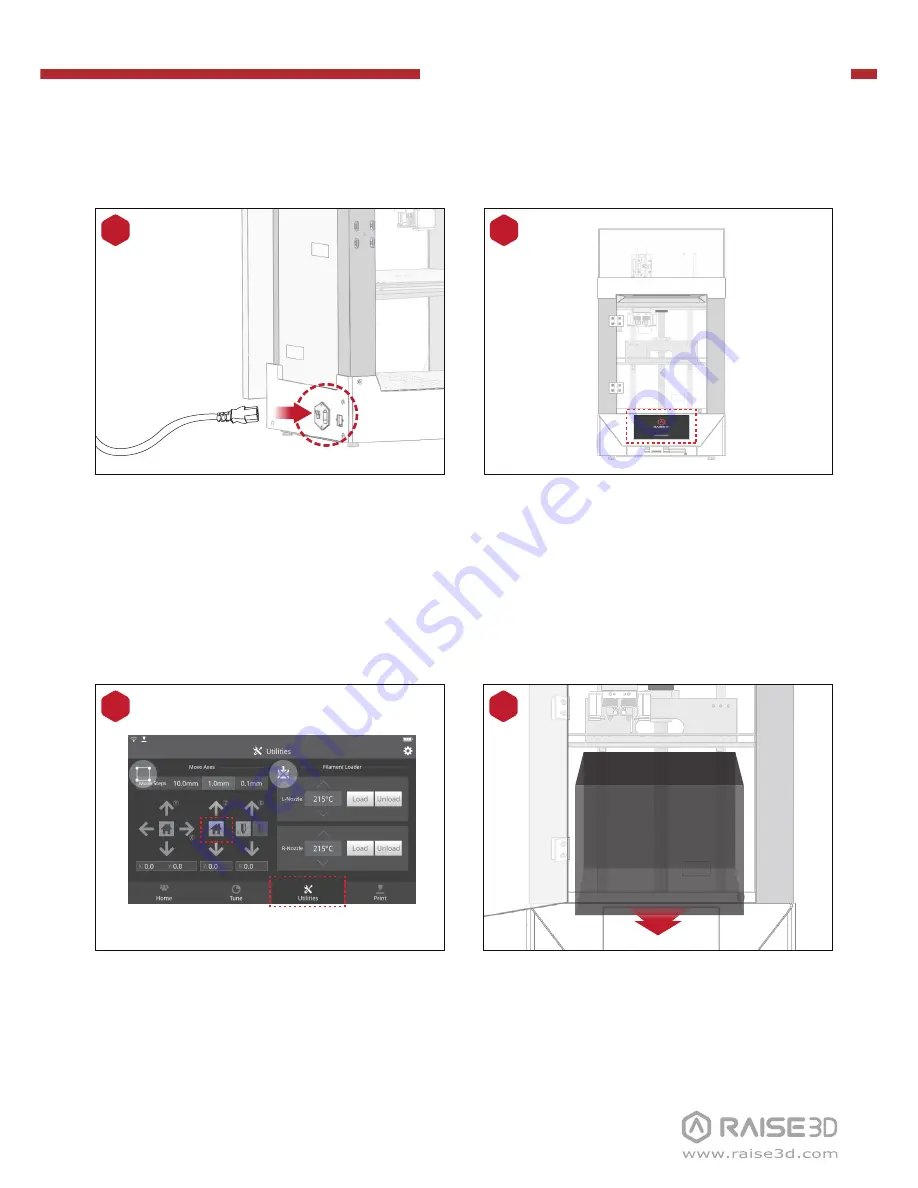

The printer will go through a start-up

sequence. When the touch screen displays

"Home", the printer is ready.

6

When the Z axis return to original position,

gently lift the build plate gently with your

hands and remove the accessory bag

under the build plate and open it for

standby.

8

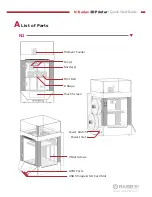

Plug in the power plug and turn the switch

on.

5

Select the “Utilities” menu on the screen.

Press Z “Home” button to raise the Z ball

screws to the highest point.

7