Pro2-Series

3D Printer

/ Quick Start Guide

B.

Hardware Installation

(continued)

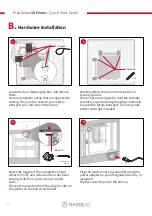

Lower the Z platform by 50mm.

To do this, set the interval at "10mm" by

selecting it in the "Move Steps" bar. This will

move the bed 10mm per arrow click. Click this

downward arrow 5 times to move Z platform

downward to 50mm.

8

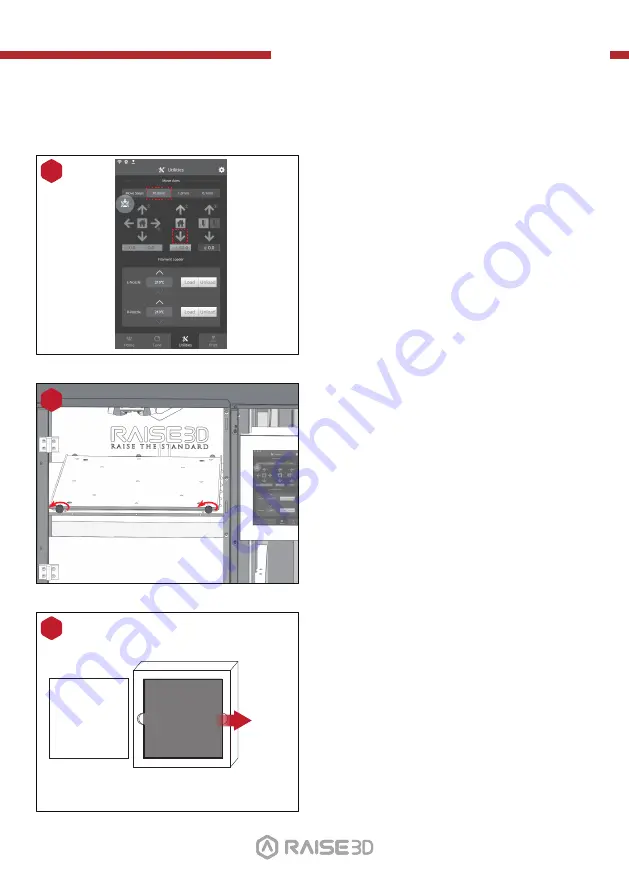

Remove the aluminum build plate from the

foam packaging.

10

Protective Foam

Cover

Build Plate

Remove!

Loose the two thumb screws on the Z platform

by rotating the two thumbscrews count-

er-clockwise.

9

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

26

24

25

27