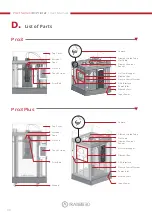

Pro3 Series

3D Printer

/ User Manual

F.

Hardware Installation

10

Adjust the flatness of the build plate.

Precise flatness helps to get a better

bottom surface of the model, avoiding

warping or the model detaching from

the build surface.

11

Adjust the matching gap between the

left and right nozzles to ensure that the

model will not be staggered in dual-col-

or printing.

12

It aims to verify whether the adjust-

ments in the previous four wizards are

appropriate.

18