Maintenance - Page 57

COPYRIGHT © 2013 SANDVIK MINING AND CONSTRUCTION OY

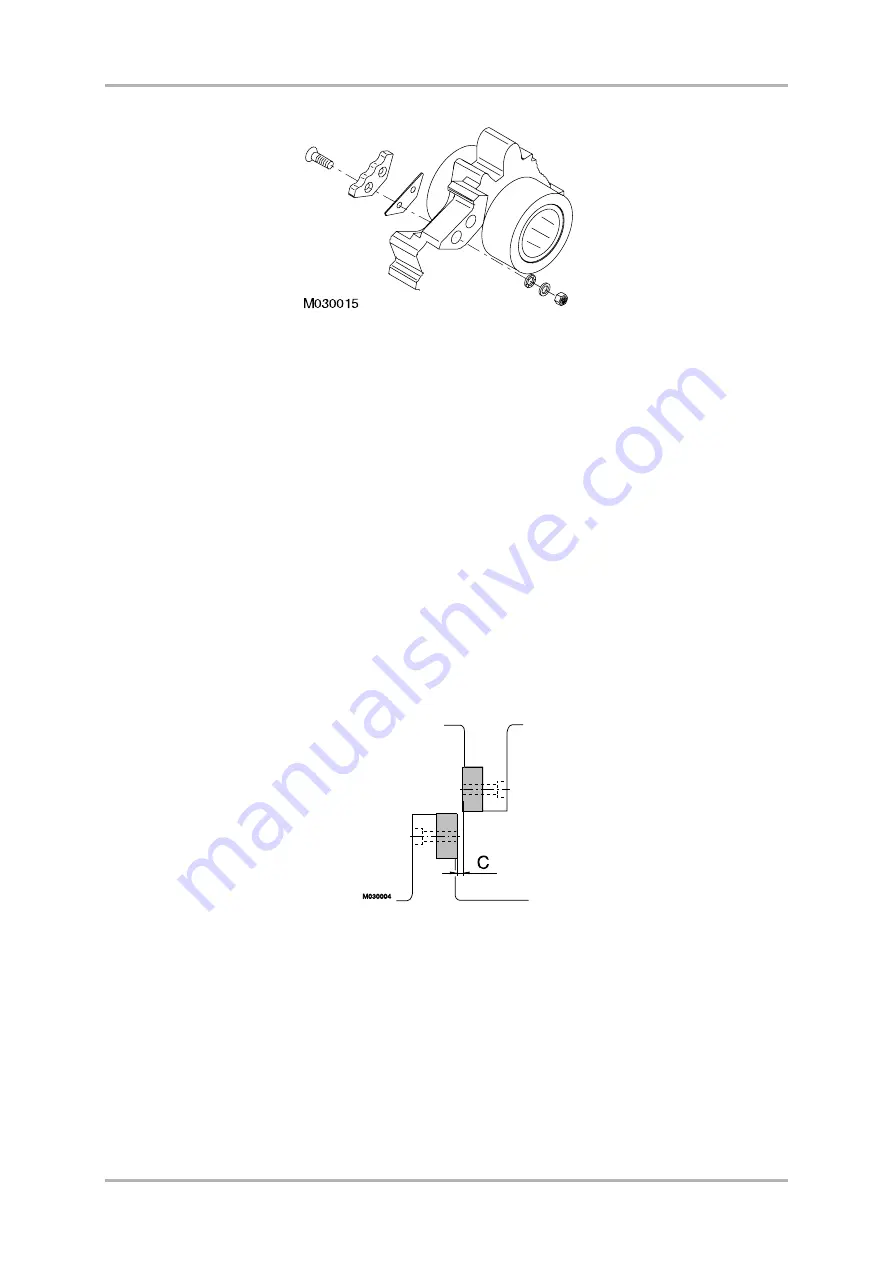

Turning and changing cutting blades A-JAW, D-JAW

RD2019 A-JAW, D-JAW, S-JAW, M-JAW

7. Remove cutting blades and shim plates.

8. Finish the surfaces by grinding, flush all burrs from cutting blade and cutter

base.

Note: If burrs remain on the surface the cutting blade will not have proper contact

with the cutter base. This will cause breakage of the cutting blade.

INSTALLATION OF CUTTING BLADES

1. Reverse the cutting blade so that unused edge can be used or install a new

cutting blade.

2. Set cutting blade on the base.

3. Fit cutting blade into cutter base with screws, lock washers and nuts.

4. Use a plastic hammer to seat cutting blade into its place with proper contact.

5. Close crusher jaws and measure the clearance between cutting blades.

6. Adjust the clearance (C) between cutting blades according to specifications. If

necessary add or remove shim plates.

7. Torque screws to the specified setting.