Maintenance - Page 73

COPYRIGHT © 2013 SANDVIK MINING AND CONSTRUCTION OY

Replacing jaws guide plates S-JAW, M-JAW

RD2019 A-JAW, D-JAW, S-JAW, M-JAW

REMOVAL OF GUIDE PLATES

Welding must occur in a workshop with proper welding tools. If you must weld

the crusher when it is installed in carrier, consult your carrier dealer for

precautions during welding.

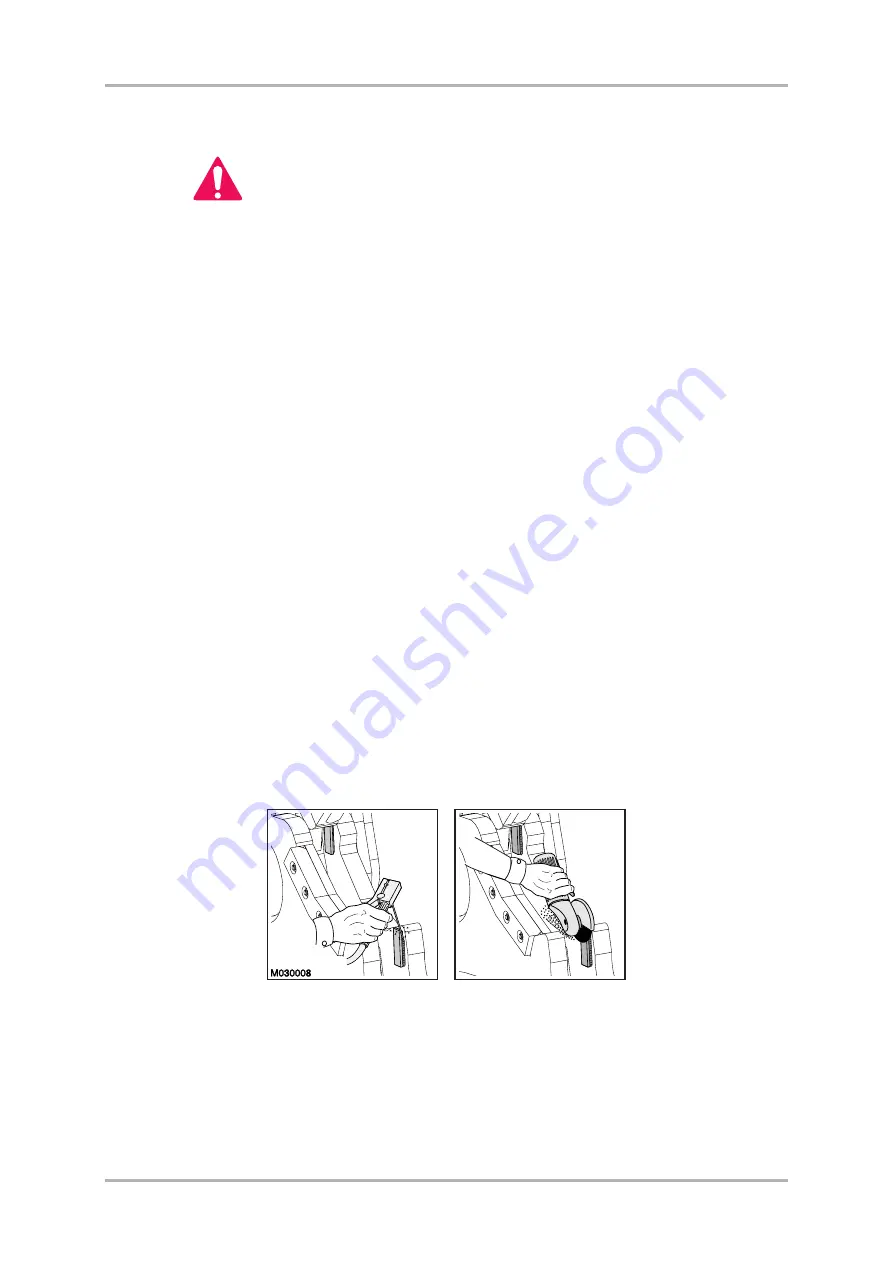

Warning! Support the crusher jaw to prevent it from closing unexpectedly

during maintenance.

1. Position the attachment on level ground.

2. Support the crusher jaws.

3. Check the clearance between crusher jaw and guide plates. Change guide plates

if clearance is more than specified.

4. Cut off the worn part by carbon arc gouging or by gas cutting at the base. Note:

Connect earth cable to the part to be repaired.

5. Repair parent by filling it with welding rod, and finish the surface by grinding.

6. Make edge preparation on the body side.

INSTALLATION OF GUIDE PLATES

1. Tack the new part with welding rod. Note: Connect earth cable to the part to be

repaired.

2. Preheat the jaw and the part to 100 °C (212 °F)...150 °C (302 °F).

3. Perform welding.

4. Close the crusher jaws to make sure that the clearance between guide plates and

upper jaw are right, use grinding machine if necessary.