IV - MAINTENANCE

21

FINAL DRIVE MAINTENANCE

CHAIN ADJUSTMENT

1.

Primary Chain Adjustment -

Place unit on stand or blocks so that the track is off the ground.

a)

Loosen track tensioner by undoing the tension nut

b)

Loosen all four 5/8 bolts in Figure 28.

c)

Chain adjustment can then take place

by using the two 3/8 bolts in Figure 28

which will slide the axle assembly to

the desired position. The chain should

have no more than .250 of slack at all

time. Track tension can be checked

by removing the foot plate.

d)

Once desired chain tension is

achieved, torque the four 5/8 bolts to 158 Lbs.

e)

Retighten track tensioner until desired track tension is reached –

NOTE:

A 180 lb person stepping on top of the track should give no more

than 1” of flex mid-span between the tension wheels and drive sprocket.

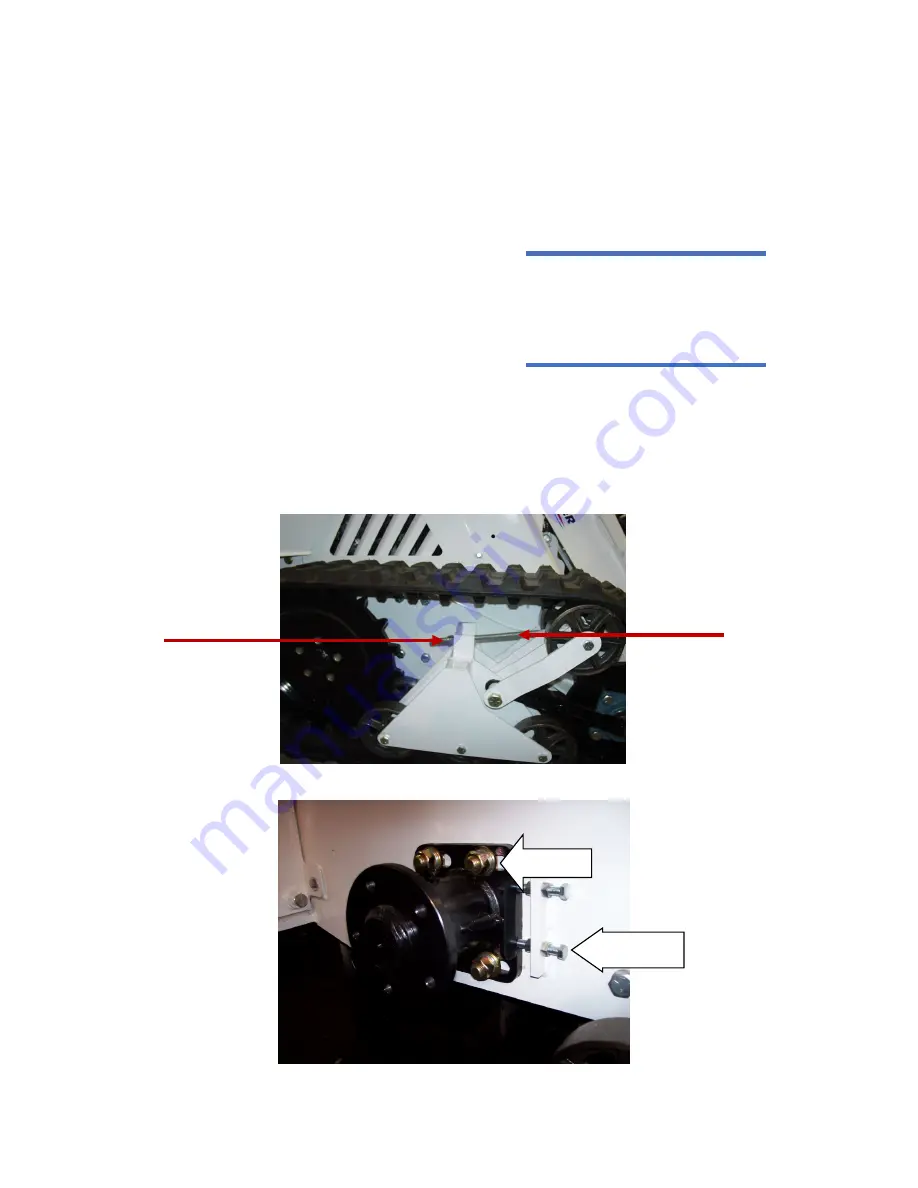

Figure 28 - 1350 Track Assembly

Figure 29 - 1350 Axle Assembly

3/8 bolt

5/8 bolt

IMPORTANT

If Chain Tension is Not

Maintained to Specification,

Chain Breakage Will Occur.

Tensioner

Tensioner Nut