TROUBLESHOOTING

TROUBLESHOOTING

11

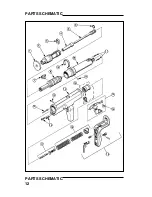

REFER TO PARTS SCHEMATIC FOR PROPER ASSEMBLY OF PARTS

- Overdriving of fasteners

- Excessive power

- Change to next lower

power level load strip

color and number.

- Soft base material

- Check base material

(see page 3)

- Tool fails to fire

- Failure to depress

- See “ Tool does not

completely

completely depress”

- Excessive dirt buildup

- After following misfire

on breech face not allow-

procedure, check firing

ing proper penetration of

pin indentation on load.

firing pin

Clean breech face

- Firing pin and/or breech

- Replace damaged parts

damaged

- Tool does not completely

- Misassembled or damaged

- Check all parts in the

depress

parts

receiver for damage or

improper assembly.

- Reduction or loss of

- Piston not being returned

- Barrel must be pulled

power

to the full rear position

completely open to

properly position the

piston.

- Worn or damaged piston

- Replace worn or

or piston ring

damaged parts

- Worn or broken pawl

- Replace pawl

- Tool cannot be cocked or

- Excessive dirt buildup

- Clean tool thoroughly

opened

- Damaged or bent piston

- Replace piston

- Broken or damaged parts

- Tag tool with warning

“Defectine- Do Not Use”.

Place in a locked con-

tainer and contact your

ITW Ramset/Red Head

representative for

service.

- Failure to index strip

- Strip not inserted in tool

- Check load strip

correctly or is damaged

Properly dispose of

damaged strip.

(See page 6)

- Damaged indexing mechanism - Contact your Ramset

Distributor for assistance

- Failure of tool to stay

- Retaining ball missing

- Contact your Ramset

closed when pointed in

Distributor for assistance

the downward position