DISASSEMBLY

DISASSEMBLY

15

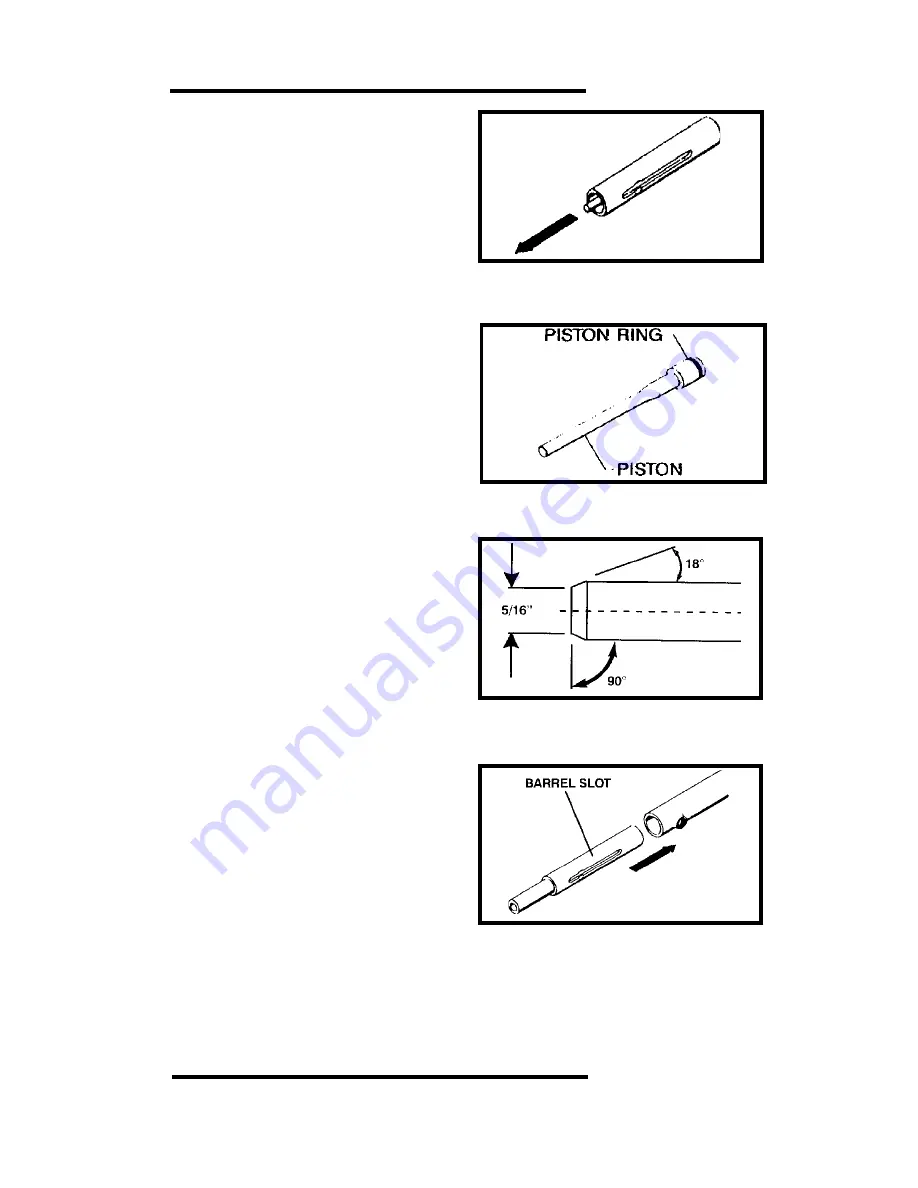

PULL THE PISTON ASSEMBLY

OUT OF THE BARREL

6.

Pull the piston assembly out of the

barrel. Check the piston for tip end

damage and that it is not bent.

To repair the tip end of the piston,

refer to the instructions below.

7.

Check the piston ring for excessive

wear, breakage or deformation that

would allow it to be less that a tight fit

in the barrel. If the piston assembly is

a loose fit in the barrel, replace it.

8.

Inspect all parts for wear or damage

and clean or replace as required.

Use detergent oil and cleaning brush.

Wipe parts dry before reassembly.

WEAR SAFETY GOGGLES WHEN

CLEANING TOOL PARTS.

9.

Check the piston tip fpr mushroom-

ing or other deformities, and grind

flat. The tip of the piston must be 90°

to the shank and grinding should only

be done by qualified personnel. The

overall minimum length of the piston

must not be less than 5 3/8”. When

less than this length, the piston must

be replaced to avoid tool damage.

10. Reassemble the tool in the reverse

order of disassembly. Align the

barrel slot with the pawl opening in

the receiver and slide the barrel

assembly back into the receiver.

ALWAYS PERFORM THE DAILY

FUNCTION TEST BEFORE

USING THE TOOL AFTER

CLEANING OR SERVICING.

INSPECT THE PISTON FOR WEAR

AND DAMAGE

GRIND THE PISTON TIP FLAT

AND BEVEL THE EDGE AT 18°

ALIGN THE BARREL SLOT WITH

THE PAWL AND SLIDE THE

BARREL INTO THE RECEIVER