FUEL CELL

FUEL CELL

8

FUEL CELL

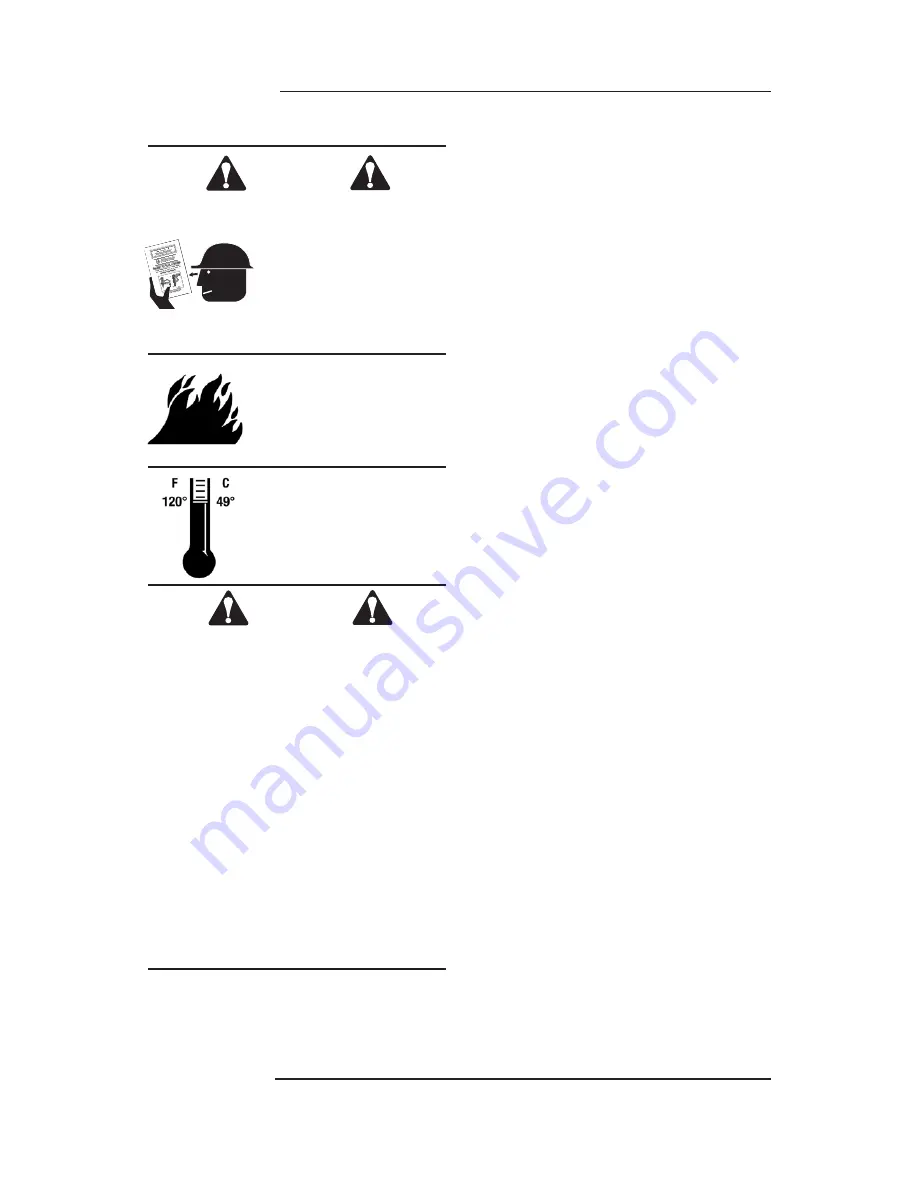

DANGER

EXPLOSION/FIRE HAZARD

Read ALL safety instructions

before using or handling the

fuel cell. Failure to follow

ALL instructions may result

in explosion or fire. This

may cause severe personal

injuries or property damage.

Keep the fuel cell away

from heat, sparks and

open flame.

Exposure to temperatures

above 120°F (49°C) may

cause the fuel cell to burst,

releasing flammable gas.

WARNING

• Sunlight can raise the inside

temperature of an unventilated

car or van to above 140°F (60°C).

• Do not puncture or attempt to

open the fuel cell; it is non-refillable.

• Do not incinerate, reclaim or recycle

the fuel cell.

• Do not smoke while installing or

removing the fuel cell.

• Do not inhale the spray.

• Keep out of the reach of children.

• Store fuel cell(s) in well-ventilated

areas only.

• Do not reuse fuel cell, adaptor or seal.

The Ramset Fuel Cell contains liquid

hydrocarbon fuel. This provides enough

fuel to drive approximately 1,000 fasteners.

The Fuel Cell is designed for proper operation

at temperatures between 15°F (-5°C) and

120°F (49°C)

There is a second container inside the fuel

cell. The inner container holds the fuel. The

space between the inner container and the

outer cylinder is filled with a gas, called the

propellant, which is under pressure.

To eject the fuel, propellant pressure

squeezes the inner fuel container, much

as you squeeze a tube of toothpaste. This

squeezing action ensures that all the fuel

is used, and that the T3 tools can operate

in any position.

Because of this container-within-a-container

design, you might hear the sound of fluid

when shaking the fuel cell after all the

fuel has been used. This is the propellant,

which remains between the containers

even after all the fuel has been expelled.

If you expose the empty fuel cell to

extreme temperatures, the propellant gas

will expand and could cause the container

to burst, releasing flammable gases.