6

GB

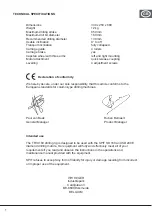

SETTING UP: ATTACHING THE DRILL MOTOR

1) Move the carriage to the upper stop and secure it in place using the knob.

2) Slide the carriage block into the carriage and lock it in place by using the capstan

wheel to tighten the locking screw.

3) Place the dovetail connection of the motor in the quick release coupling and fix the

motor with the capstan wheel.

4) Select the correct machine speed.

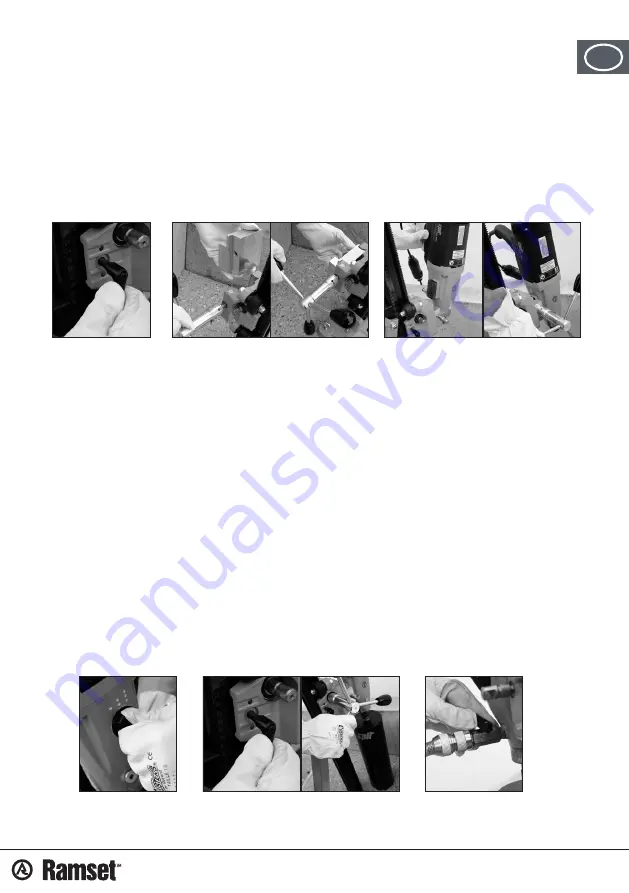

5) While holding the capstan wheel in position, loosen the brake handle.

Bring the crown of the drill bit in contact with the surface of the material to be drilled,

then back it off by a few millimetres.

6) Open the water tap and adjust the water flow.

7) Switch the motor on. Consult the operation and maintenance manual for the SD 160

or SD 200E with regard to selecting the speed and other precautions.

Start drilling. Drill slowly and cautiously for several millimetres after penetrating the

surface, and then maintain a constant force on the capstan wheel for the remainder

of the bore.

ALWAYS SECURE THE CARRIAGE USING THE BRAKE HANDLE BEFORE

RELEASING THE CAPSTAN WHEEL!!

1

3

2

5

4

6

Summary of Contents for TRIX 160

Page 1: ...Operator s manual and maintenance instructions TRIX 160...

Page 2: ...2...

Page 11: ...8 GB NOTES...