SBRGB

•

11

•

Use the other hand to re-heat the solder dab to melt it to the component

connection.

•

Let the solder cool and then let go with the tweezers. Inspect orientation

and make sure the part is square over the correct pads. Make sure stray

solder connections don’t overlap or short across the adjacent pads.

•

Apply solder to the rest of the pads.

•

Apply a touch more solder to the initial pad to make sure there is a good

solder joint. The rosin core flux will clean the joint and insure stability.

•

If you have too much solder and wish to remove it, use a solder sucker or

solder wick to “soak up” the extra solder. Solder bridges on SMT IC pins

are a frequent occurrence so you should always have some solder wick

handy.

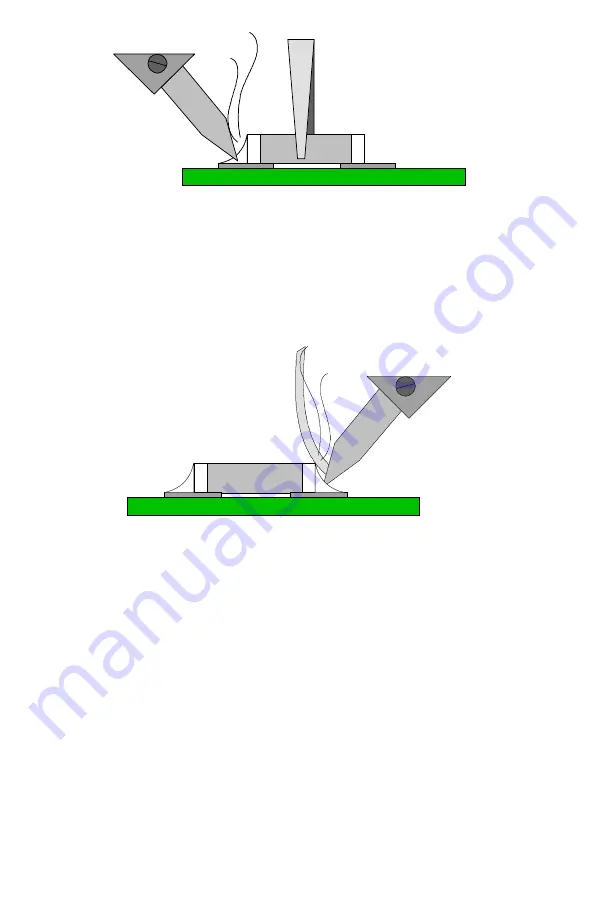

In the case of through hole components:

•

Insert the part (oriented correctly) into its holes or pads on the PC board.

•

If helpful, gently BEND the parts wire leads or tabs to hold it in to make

soldering easier.

•

SOLDER ALL wires or pins of the part. Whether it’s two wires or pads of a

resistor or all pins or pads of an IC socket.