17

FIGURE 13

Slide spacer #101 over long end of shaft and place

against gear hub. Apply grease to end of shaft,

opposite gear. Apply grease to bushing in gear housing

#22. Place greased end of shaft through bushing in

gear housing #22. Place gasket #80 onto gear

housing cover #16. Apply grease to gear end of shaft

andcover bushing. Place cover onto shaft and secure

to housing with eight #47 capscrews. Tighten

capscrews to 53 Nm (39 ft-lb) each.

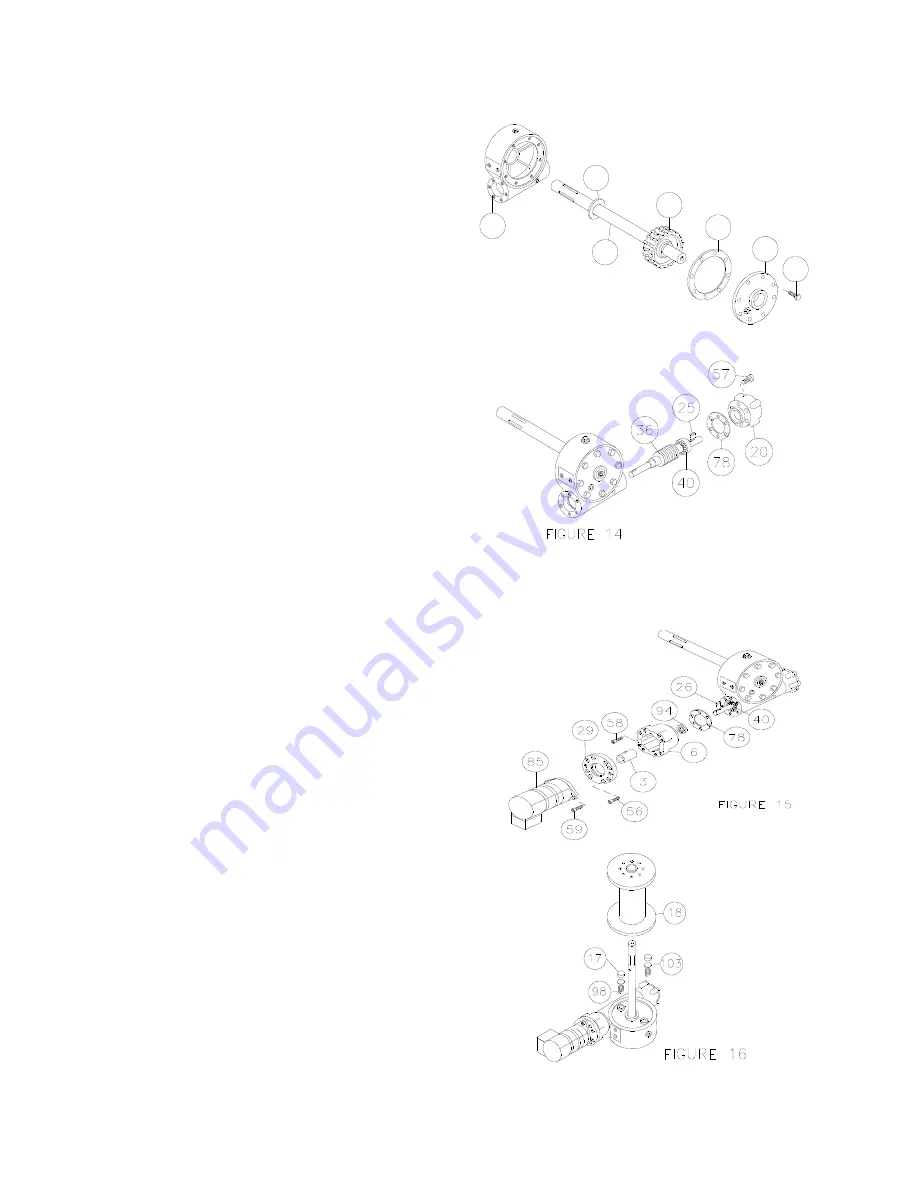

FIGURE 14

Press bearing #40 onto worm #36. NOTE: Be sure that

thick shoulder of bearings outer race (side with

manufacturer's name and part number) is out, away

from worm threads. Press bearing and worm into gear

housing. Slip gasket #78 onto brake housing #20. Use

six capscrews #57 to secure brake housing

to gear housing. Tighten capscrews to 61 Nm (45 ft-lb)

each. Place key #25 into keyway of worm #36. Refer

to page 8 for reassembly and checking of worm brake.

FIGURE 15

Press bearing #40 onto worm and into housing.

NOTE:

Be sure that thick shoulder of bearings outer race (side

with manufacturer's name and part number) is out,

away from worm threads. Attach adapter #6 to gear

housing using six capscrews #58. Tighten

capscrews to 61 Nm (45 ft-lb) each. Insert key #26

into keyway of worm shaft. Slide coupling #3 over end

of worm shaft. Attach adapter plate #29 to adapter

using eight capscrews #56. Tighten capscrews to 28

Nm (21 ft-lb) each. Place motor shaft, with key in

keyway, into coupling. Secure motor #85 to adapter,

using two capscrews #59. Tighten capscrews to 138

Nm (102 ft-lb) each.

FIGURE 16

Place winch with gear housing cover down on work

bench. Drum shaft should be in vertical position. Set

springs #98 into pockets of gear housing with drag

brakes #17 on top of disc #103 and springs. Apply

grease to shaft and drum bushings. Slide drum

assembly #18 onto drum shaft as shown.

101

22

32

16

80

19

47

FIGURE 13