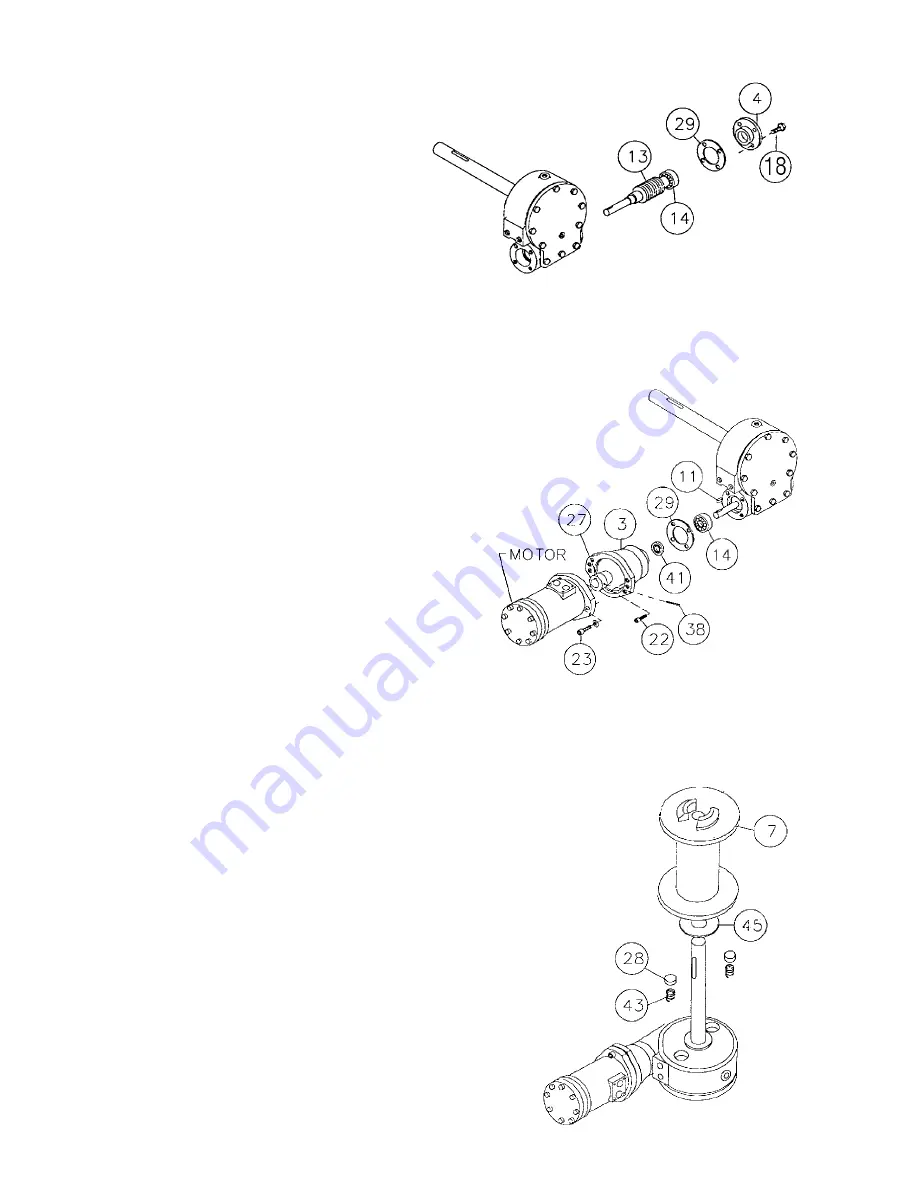

12.Press bearing (item #14) onto

worm (item #13). NOTE: Be sure

that thick shoulder of bearings

outer race (side with manufactur-

er's name and part number) is

out, away from worm threads.

Press bearing and worm into gear

housing. Slip gasket (item #29)

onto bearing cap (item #4). Use

four capscrews (item #18) to secure cap to gear

housing. TIGHTEN CAPSCREWS TO 8 FT.

LBS. (10.8 Nm.) EACH.

13.Press bearing (item #14) onto worm and

into housing. NOTE: Be sure that thick

shoulder of bearings outer race (side with

manufacturer's name and part number) is

out, away from worm threads. Place gas-

ket (item #29) onto adapter (item #3).

Attach adapter to gear housing using four

(4) capscrews (item #22). TIGHTEN

CAPSCREWS TO 12 FT. LBS. (16.3 Nm.)

EACH. Insert key (item #11) into keyway

of worm shaft. Slide tapered end of cou-

pling (item #27) over end of worm shaft.

Be sure roll pin (item #38) is in coupling.

Place motor shaft, with key in keyway, into cou-

pling. Secure motor to adapter, using two (2)

capscrews (item #23) and lockwashers.

TIGHTEN CAPSCREWS TO 75 FT. LBS. (102

Nm.) EACH.

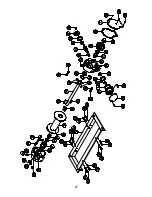

14.Place winch with gear housing cover down on

work bench. Drum shaft should be in vertical

position. Slide thrust washer (item #45) over

drum shaft and slide downward until washer

rests on gear housing. Set springs (item #43)

into pockets of gear housing with drag brakes

(item #28) on top of springs. Slide drum

assembly (item #7) onto drum shaft with

drum jaws upward.

13