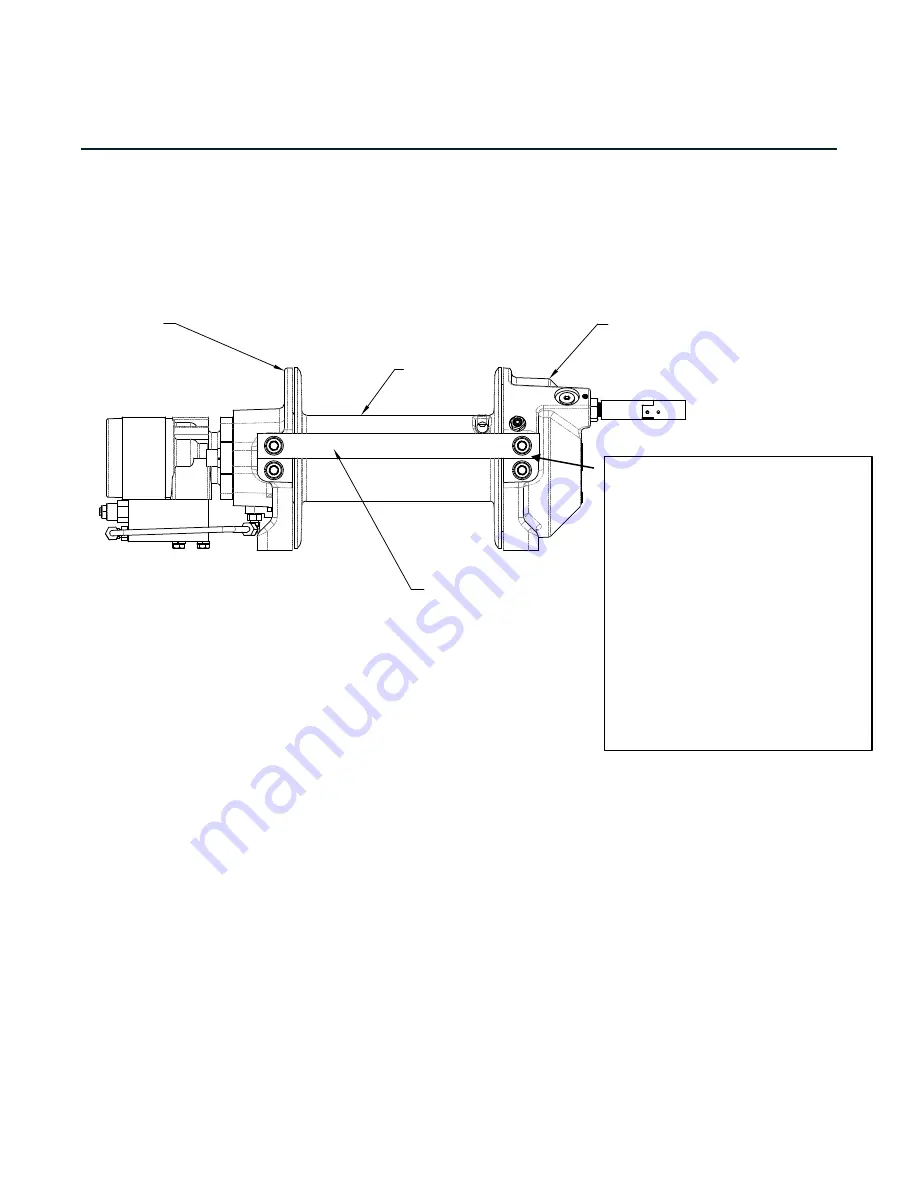

Installation Details

Winch Mounting

ESSENTIAL MOUNTING INSTRUCTIONS TO MAINTAIN ALIGNMENT OF PLANETARY WINCH

COMPONENTS:

It is most important that this winch be mounted securely so that the three major sections (the

motor end, the cable drum, and the gear housing end) are properly aligned. Excessive bushing

wear and difficulty in free-spooling are usually symptoms of misalignment.

If the winch is foot mounted, then at least one tie-plate must remain mounted at midpoint of

winch to maintain alignment. It is always preferred to use BOTH tie-plates in the final installed

configuration.

When mounting the winch with other than the recommended Ramsey Angle Kit, the mounting

hole patterns described in the Dimensional drawings of this manual should be used. The

mounting surface must be flat within .015 inch and sufficiently stiff to resist flexing. If a steel

plate is used for foot mounting, it should be .750 inch thick. For this mounting application eight

(8) 1/2-13NC x 1-1/2” long grade 5 cap screws with lock washers will be needed to mount winch.

Cap screws should be tightened to 55 ft-lb (75 Nm) torque.

NOTE: If angles or a steel plate are used in mounting winch, tie-plates provided with winch are

to be attached to the remaining mounting pads, whether they be side or foot.

* CAUTION:

If longer bolts

(minimum grade 5) are

substituted to mount winch or to

mount a roller guide at the side

mount pads, bolt length must be

such as to allow a minimum of

.50 inch thread length

engagement in the tapped holes

in side of each end bearing. Use

of excessive length bolts will

damage the winch and prevent

free-spool of the drum. Torque

bolts to 55 ft-lbs. (75 Nm).

914307

11

GEAR HOUSING EN

DRUM

MOTOR END

FOOT MOUNT

SHIPPING STRAP

Summary of Contents for HD-P 4000

Page 4: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 6: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 10: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 14: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 16: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...