12

HERCULES 50K

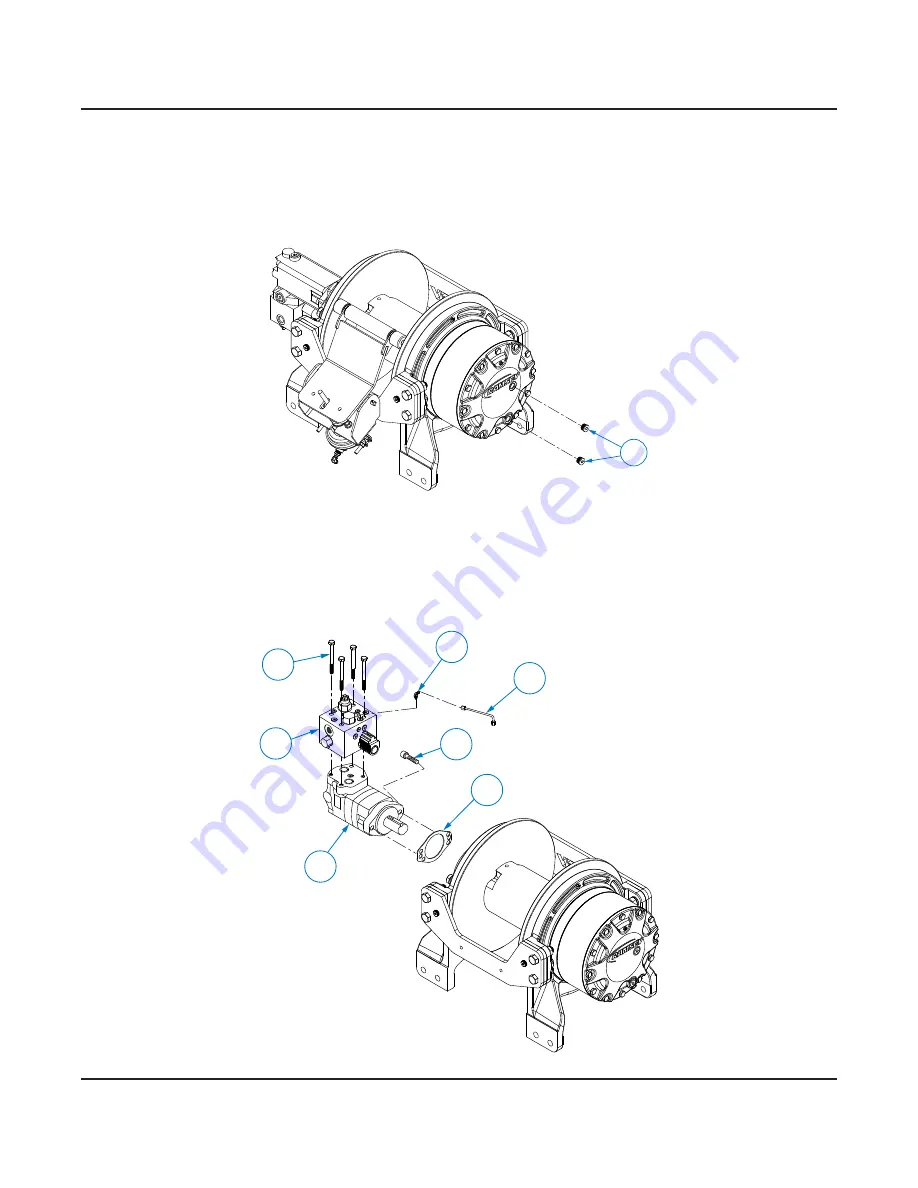

Disassembly

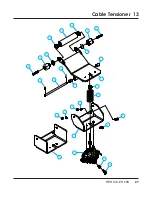

1. Drain oil from gear housing cover by removing o-ring plugs #42. Remove tensioner assembly.

2. Disconnect hose #50 from elbow #43 on valve #51 and fitting #29 on brake #36. Remove

motor #39 and gasket #36a by removing (2) cap screws #20. Remove valve #51, if needed,

from motor by loosening (4) cap screws #14.

36a

39

51

14

20

43

50

42

7

Instructions for Overhaul