4

WINCH INSTALLATION

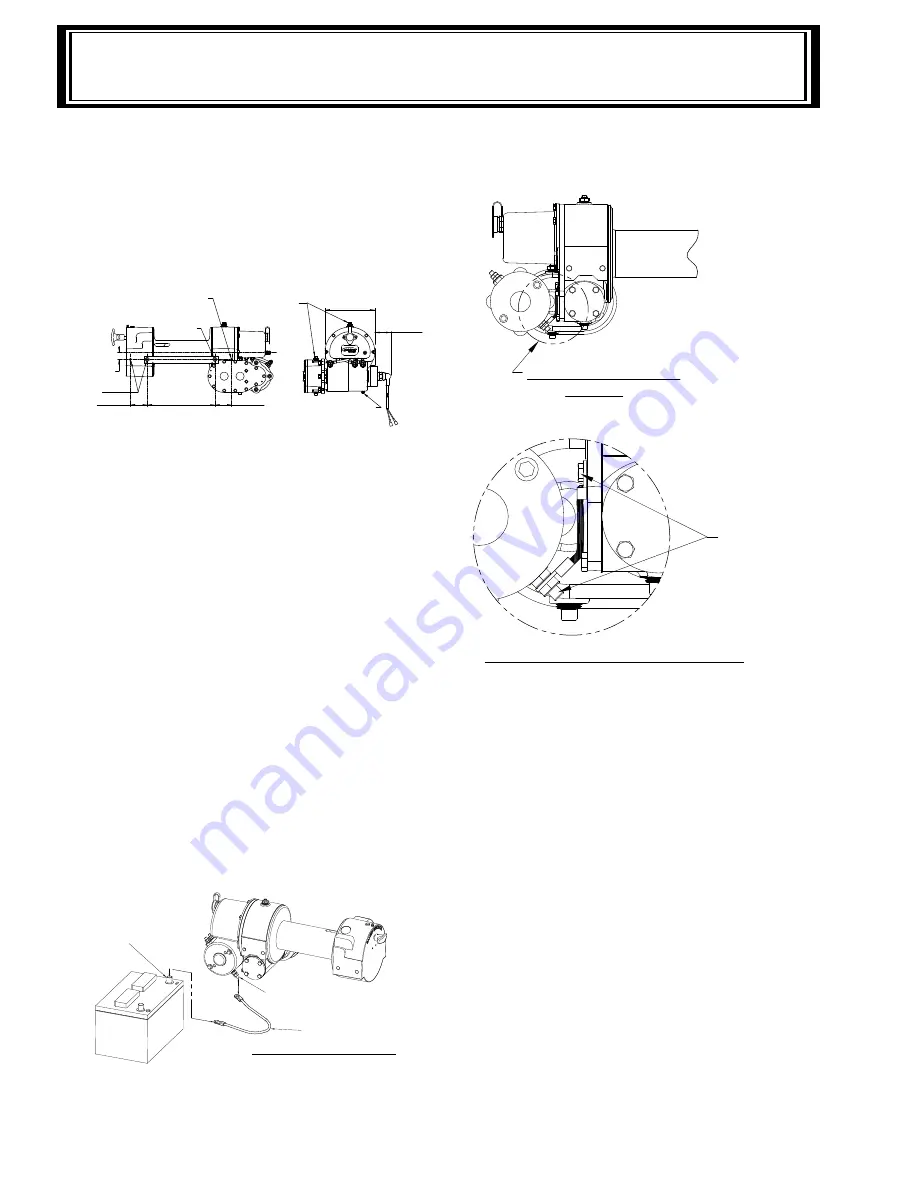

Winch Installation

NOTE: The winch must be mounted to angles

9 x 63 x 63 (3/8” x 2-1/2” x 2 1/2” minimum)

high strength 344,000 kPa (50,000 PSI) yield

steel angle or in a frame with both sides of the

clutch housing and gear housing bolted to the

angles or frame.

See diagram below for recommended

mounting dimensions.

Note various thread depths of mounting holes

and use correspondingly different bolt lengths

for proper mounting.

Substitution of attaching hardware items) bolts, nuts, or

washers) different from those supplied with your winch

mounting kit can lead to failure causing damage or serious

injury. Use a socket head mounting bolt on side with Spur

Gear Housing (see diagram) to prevent clearance prob-

lems. Use SAE grade 5 bolts or better.

Electrical Connections and Operations

For normal self-recovery work, your existing electrical sys-

tem is adequate. Your battery must be kept in good condi-

tion. A fully charged battery and proper connections are

essential. Run the vehicle engine during winching opera-

tion to keep battery charged.

Connect red cable from stud on plastic solenoid cover on

winch to emergency stop solenoid. Important: Hold inner

nut with end wrench while tightening outer nut. Install

emergency stop switch and solenoid per kit # 282067

(12V) or 282068 (24V) as applicable.

Connect black cable from motor isolated ground terminal

to negative battery terminal (as shown above). A good

electrical ground is required for proper performance.

In applications where the chassis is non-grounded, a jumper wire

(#440315) will be required between the winch and the motor isolated

ground terminal. (See Illustration Below)

The remote control switch is waterproof and has push

button stations on either side. It is designed this way to

prevent quick winch reversals, which lead to solenoid fail-

ure. Make sure the winch motor has stopped fully before

reversing.

When first setting up your winch, follow the directions for

inserting the proper “IN” or “OUT” label in the thumb but-

ton. The switch is also color coded to aid you in determin-

ing the direction your winch will run.

Maintenance

Check monthly the action of the sliding clutch, making sure

it is fully engaging and disengaging with the rope drum.

With the clutch in the engaged position, remove the plastic

plug in top of the housing and observe if the clutch is fully

engaging. If clutch is not fully engaging, inspect the clutch

shifter assembly parts, check for damage or excessive

wear and replace as necessary. Observe the jaws on both

the clutch and rope drum, checking for rounding of the

driving faces.

WINCH WILL NOT OPERATE UNLESS

GROUND CABLE IS INSTALLED FROM THE

ISOLATED GROUND TERMINAL TO THE

NEGATIVE BATTERY POST.

(SEE DIAGRAM BELOW)

JUMPER CABLE

(#440315) MUST

BE INSTALLED

ON WINCH FROM

MOTOR ISOLATED

GROUND STUD TO

GEAR HOUSING

COVER BOLT AS

SHOWN FOR NON

GROUNDED CHAS-

SIS APPLICATIONS.

61,2 MM

2.41 IN.

7.44 IN.

188,8 MM

REMOVE RUBBER COVER FROM

RELIEF FITTINGS BEFORE PUTTING

WINCH INTO USE.

2.50 IN.

63,5 MM

1.12

28,5

DEEP THREADS

(EACH SIDE)

3/8-16 x .75"

257,2 MM

10.19 IN

63,5 MM

2.50 IN.

ATTACH BLACK GROUND CABLE

TO THE ISOLATED GROUND

TERMINAL OF THE WINCH MOTOR

ON SIDE WITH SPUR GEAR HSG.

USE SOCKET HEAD MTG BOLTS

(EACH SIDE)

3/8-16 x 0.50" DEEP THREADS

3/8-16x1" DEEP

THREADS

(EACH SIDE)

NEGATIVE BATTERY POST

GROUND CABLE

ISOLATED GROUND

TERMINAL

Isolated Motor Ground

SEE ILLUSTRATION

BELOW

Non-Grounded Chasis Applications

For non-grounded chassis applications a jumper wire

(#440315) is required to ground the solenoid assembly.