7

5. Determine position shifter knob needs to

be for your application.

Note:

Shifter

knob cannot be positioned too low or it

will interfere with the feet on the Gear

End Bearing (see Range of Position in

Figure 8).

6. To position the shifter knob, place lock-

ing ring in end bearing with stop post

approximately 180° from where shifter

knob needs to be positioned. Place cam

ring over locking ring in proper position

and confirm that shifter knob will move

from engaged to disengaged position

without interference. Mark position of

stop post on end bearing.

7. Remove cam ring and locking ring from end bearing. Insert springs (item #39) into end bearing. When you replace the

locking ring (item #35) over the springs, be sure the springs compress down into their recesses, and don’t bend side-

ways.

8. Reassemble Gear Housing as shown in Figure 7. Make sure locking ring is positioned with stop post at marked loca-

tion. The capscrews (item #22) for the retainer should be tightened to 40-45 in-lbs.

Do not over-tighten.

9. Place Gear Housing over the stacked gears, etc. that you removed in step 3. Gently work the housing over the stack,

turning it as needed to mesh the planetary gears with the ring gear in the housing. Once they are all in the housing, flip

the assembly over. Align the Gear Housing Cover and gasket with the holes in the ring gear. Replace the (6) capscrews

that hold the Gear Housing Cover onto the Gear Housing. Tighten securely.

10. Move the Shifter to the Disengaged position.

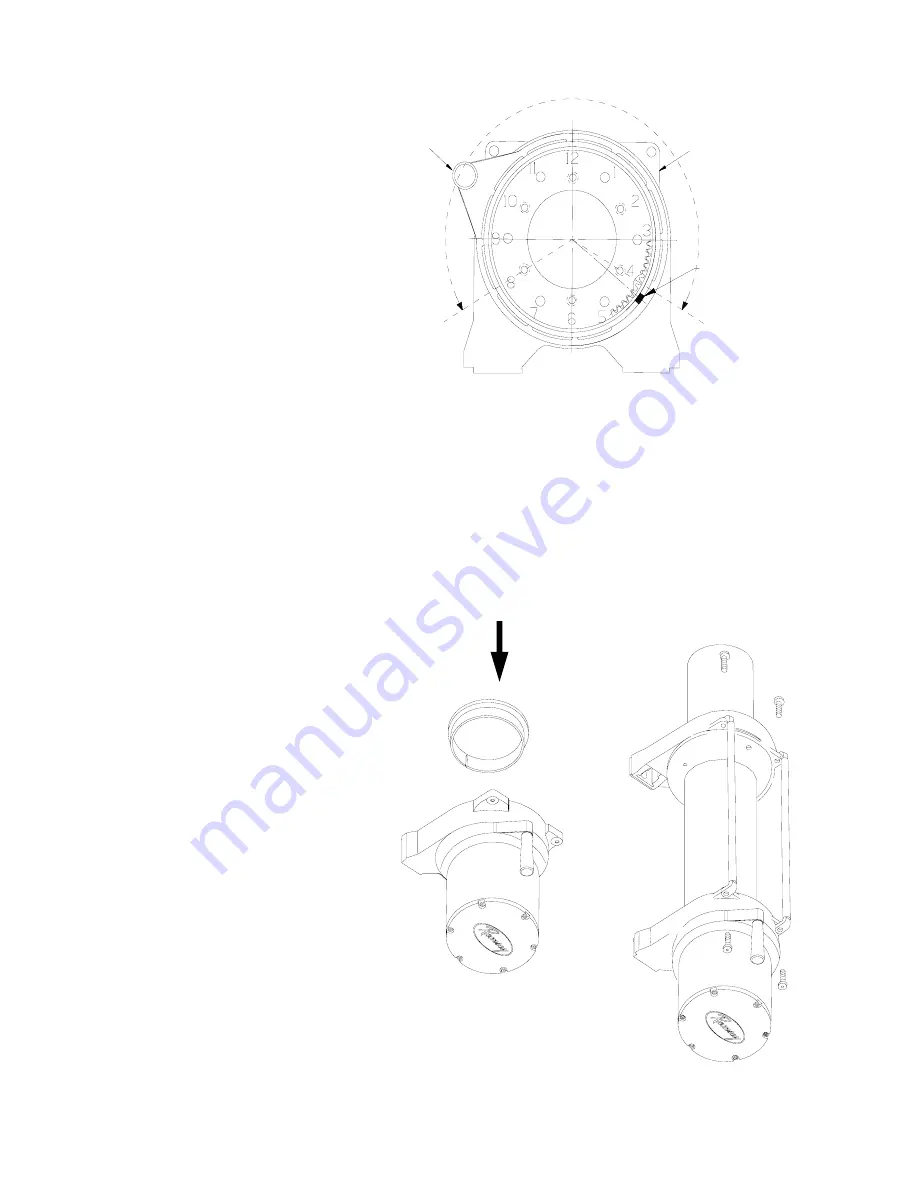

11. Turn the Gear Housing over and set it on the

work bench with the Gear Housing Cover

down. See Figure 9.

12. Install the drum bushing into the Gear Hous-

ing, confirming that the slot in the bushing is

aligned with the key in the end bearing. Pick

up the rest of the winch (drum and motor

end), and holding the drum, lower the winch

onto the gear end. Stab the shaft into the

gear end--you may need to turn the drum

slightly to get the shaft to go all the way in.

13. Place the tiebars on the motor end and gear

end and fasten using (4) screws. Tighten

securely.

14. Once the winch is reassembled, turn it so

that it is sitting on its feet. Confirm that the

cable will freespool when the shifter is in the

Disengaged position. Connect up the winch

temporarily and confirm that the cable

spools when the shifter is in the Engaged

position.

RANGE OF POSITION

FOR SHIFTER KNOB

END BEARING

STOP POST ON

RING GEAR LOCK

CAM RING

SHIFTER

KNOB

FIGURE 8

FIGURE 9

Инструкция RAMSEY REP 9.5e

www.bigfoottrade.kz