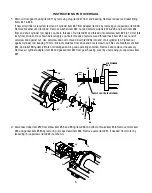

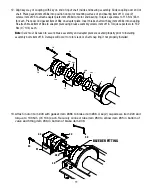

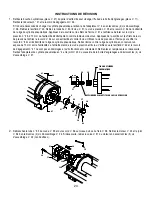

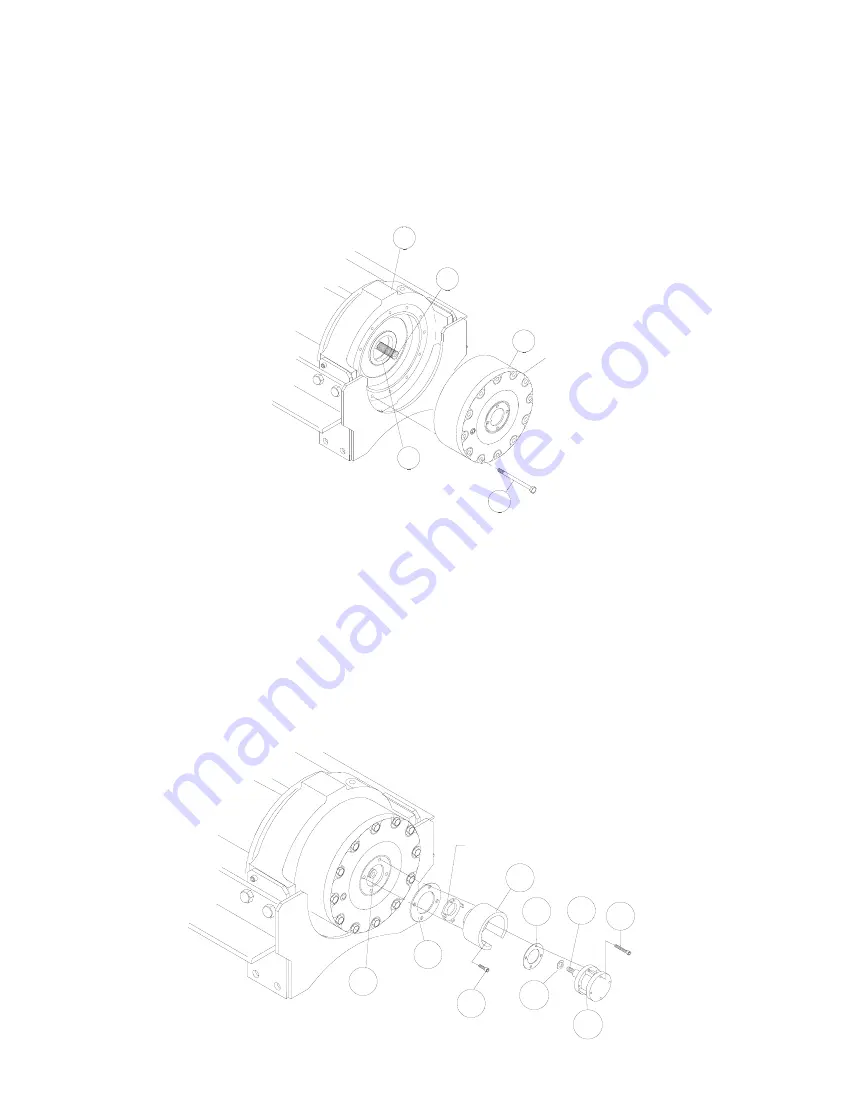

10. Apply RTV sealing compound to ring gear mounting surface of end bearing item #10. Place ring

gear onto end bearing, aligning holes in ring gear with holes and gear housing end bearing. Use

(2) capscrews to temporarily secure ring gear to end bearing.

Place (2) gear carrier assemblies into ring gear meshing carrier gears with ring gear. Remove

(2) temporary capscrews, making sure that ring gear and carrier assemblies are securely against

end bearing item #10. Apply RTV sealing compound to cover mounting surface of ring gear item

#3) and attach cover to ring gear. Use (12) capscrews item #17 to secure gear box to gear hous-

ing end bearing. Torque capscrews to 53 Nm (39 ft lb) each, in criss-cross pattern.

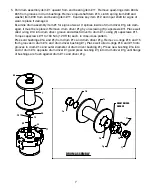

11. Slide input sun gear over shifter shaft item #13 and mesh with teeth of input carrier. Apply

grease to input thrust washer and place into slots of air cylinder adapter item #4. Place gasket

item #40 into position on gear box cover with sealer and attach adapter to cover using (4) cap-

screws item #21 Apply Loctite PST thread sealer to threads of capscrews. Torque capscrews to

18 Nm (13 ft lb) each, in criss-cross pattern.

Pull rod from air cylinder as far as possible. Slide washer item #30 over setscrew item #25 and

against nut attached to air cylinder rod. Place setscrew into hole of shifter shaft item #13. Attach

new air cylinder item #37 and gasket item #40 with sealer, to adapter using (4) capscrews item

#26. Apply Loctite PST thread sealer to threads of capscrews. Torque capscrews to 7 Nm (5 ft

lb) each, in criss-cross pattern.

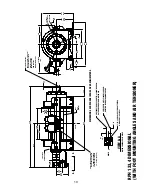

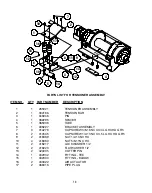

RING GEAR

10

COVER

GEAR HOUSING

3

17

16

13

13

WASHER

INPUT THRUST

4

37

26

25

40

21

30

39

10

Summary of Contents for RPH 133,4

Page 19: ...16...