5

LOWER SUSPENSION ARM ASSEMBLY

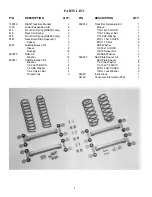

Bushing & Sleeve Installation

1.

≤

Lubricate the outside diameter of two red

urethane bushings, from kit 8597, with a

silicone spray or a mild solution of soap and

water.

2.

≤

Press the bushings (Do Not Hammer) into

one end of a new lower suspension arm. See

figure 1.

Figure 1

3.

≤

Lubricate the outside diameter of a sleeve,

from kit 8597, and the inside diameter of the

installed urethane bushings.

4.

≤

Press the sleeve into the bushings.

NOTE: If necessary, use a bench vise or C-

clamp to press the bushings and sleeves into

the suspension arm. Do not use a hammer.

5.

≤

Pre-grease arm assembly with a grease

gun. Make sure not to blow the bushings out

of the assembly. Stop when grease appears

at the end of the bushing grooves.

6.

≤

Repeat steps 1 through 5 for the remaining

suspension arm ends, bushings, and sleeves.

FRONT SUSPENSION

Shock & Spring Removal

1.

≤

Park vehicle on a level surface, set the

parking brake and chock rear wheels.

2.

≤

From inside the engine compartment,

remove the upper stud nut, retainer and

grommet from both front shock absorbers.

3.

≤

Raise the front of the vehicle and support

the frame with jack stands.

4.

≤

Remove the front wheels.

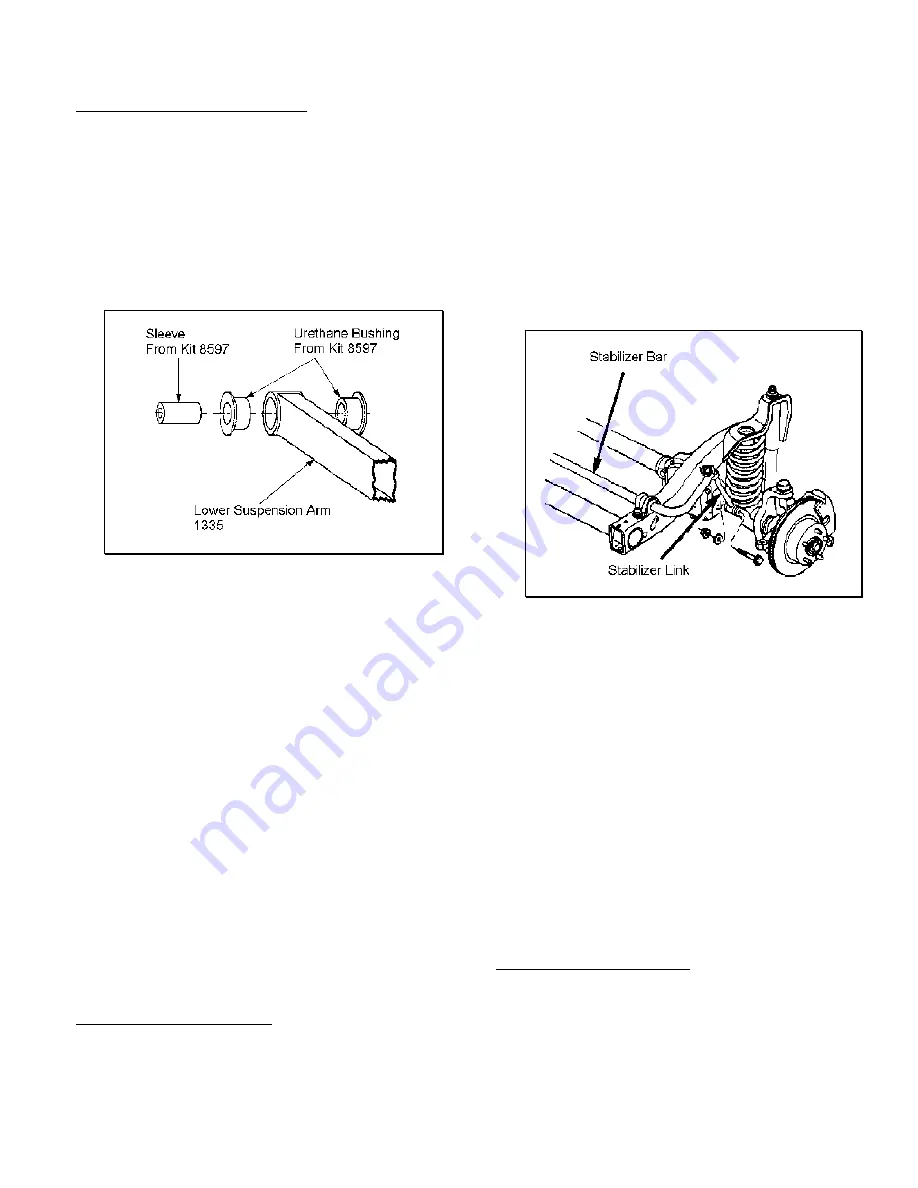

5.

≤

Position a hydraulic jack under the front axle

for support. Remove the stabilizer link lower

nut and bolt from both sides of the front axle.

See Figure. 2

Figure 2

6.

≤

Remove the shock absorber lower nuts and

bolts from the axle bracket. Remove both

shocks and discard. DO NOT REUSE

ORIGINAL SHOCK ABSORBERS.

7.

≤

Lower axle and remove hydraulic jack.

8.

≤

Remove the rubber bump stops and bump

stop mounts.

9.

≤

Remove the coil spring retainer bolts and

retainers.

10.

≤

Push down on the axle and remove each

coil spring.

Lower Arm Replacement

1.

≤

Support the front axle with a hydraulic jack.

2.

≤

Paint or scribe alignment marks on the

adjustment cams and axle brackets for

installation reference. See Figure 3.