59

11.3. Periodical maintenance

Operation to be carried out with

the machine under pressure.

L

Discharge the water from the boiler with hot water

GHOLYHU\VZLWFK

L

Wait until the machine has returned to heat equi-

librium before reuse.

11.2. Weekly

Operations to be carried out with the machine

operative and under pressure.

L

3ODFHWKHVXSSOLHGEOLQG¿OWHULQWKH¿OWHUKROGHU

put in a spoonful of detergent in powder for coffee

PDFKLQHVDQG¿WWKH¿OWHUKROGHULQWKHXQLWWREH

cleaned.

L

Press the coffee dispensing button and draw water

for approx. 30 seconds.

L

Stop and start dispensing several times until clean

water comes out of the discharge unit tube.

L

5HPRYHWKH¿OWHUKROGHUWDNHRXWWKHEOLQG¿OWHUDQG

LQVHUWDQRUPDORQH5HSODFHWKH¿OWHUKROGHURQWKH

XQLWDQGULQVHE\GUDZLQJZDWHUVHYHUDOWLPHV

L

0DNHDFRIIHHWRHOLPLQDWHDQ\XQSOHDVDQWWDVWH

Cleaning the filters and delivery heads

Operation to be carried out when the machine is off

and cold.

L

Prepare a solution of 4 sachets of detergent powder

Code

69000124

dissolved in a litre of boiling water

in a stainless steel, plastic or glass recipient (

NOT

ALUMINIUM OR IRON

)

.

L

5HPRYHWKH¿OWHUVDQGLPPHUVHWKHPZLWKWKH¿OWHU

holders in the prepared solution, leaving them for

at least 10/20 minutes (all night is better).

L

Remove them from the container and rinse them

WKRURXJKO\LQUXQQLQJZDWHU

Tank cleaning

(Fig.10 - 11)

L

Remove the cup-stand grille 1 at 2 (Fig.10) and

clean.

L

Check and clean the drainage sump 3 (Fig.11),

UHPRYLQJDQ\VOXGJHZLWKWKHKHOSRIDVSRRQ

11. MAINTENANCE

Maintenance operations have to be carried

out when the machine is off and cold and

the plug is disconnected. Some particular

operations have to be effected when the

machine is operating.

Do not clean the machine by using metal or

abrasive devices, such as steel wool, metal

brushes, needles, etc. or general detergents

(alcohol, solvents, etc.)

When necessary, use special detergents

for coffee machines that can be bought in

specialized service centres.

11.1. Daily

(Fig.9)

Use a clean cloth or sponge that does not leave hairs

RUÀXIISUHIHUDEO\FRWWRQRUOLQHQ

L

&DUHIXOO\FOHDQWKHRXWVLGHVXUIDFHIROORZLQJWKH

JUDLQRIWKHVDWLQ¿QLVKRQWKHSDUWVLQVWDLQOHVV

steel.

L

Clean the steam and hot water spouts, check that the

QR]]OHVDUHQRWHQFUXVWHGLIWKH\EHFRPHHQFUXVWHG

be careful not to deform or damage them).

L

&OHDQWKHVSUD\XQLWVDQGWKHVHDOVXQGHUWKHFD

-

VLQJRIWKHGHOLYHU\XQLWVXVLQJWKHVSHFLDOEUXVK

supplied

L

5HPRYHWKH¿OWHUKROGHUVRIWKHPDFKLQHDQGUH

-

PRYHWKH¿OWHUVDQGWKHFODPSZKLFKVHFXUHVWKH

¿OWHUXVHDEUXVKWRUHPRYHDQ\FRIIHHGHSRVLWV

DQGULQVHZLWKKRWZDWHULQRUGHUWRGLVVROYHDQ\

grease deposits.

Model S1 TANK

Operation to be carried out when the ma-

chine is off and cold and the plug is discon-

nected.

L

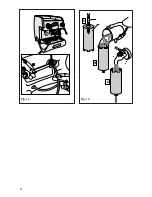

5HPRYHWKHOLGRQWKHZDWHUWDQN

L

Remove the air trap

C

and softener

A

)LJ

L

7DNHRXWWKHZDWHUWDQNHPSW\DQGFOHDQLW

L

7KRURXJKO\ULQVHWKHZDWHUWDQNDQGUHSODFHLWLQ

WKHPDFKLQH

L

Place the air trap in its guide and the softener

KRUL]RQWDOO\RQWKHERWWRPRIWKHZDWHUWDQN

L

Fill the tank with clean water and close the lid.

If the air trap is not in the correct position,

the machine cannot heat or indicate a lack

of water in the tank.

Summary of Contents for EPOCA E

Page 4: ......

Page 6: ......

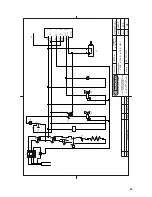

Page 8: ...8 1 2 3 4 5 6 8 7 9 10 mod S1 Fig 3 a 1 2 3 4 5 6 8 7 9 10 mod E1 Fig 3...

Page 9: ...9 Fig 4 Fig 5 4 L o v a t o L 2 3 8 G 1 30mm 1 2 3 4 5 6 8 7 9 10 12 mod S1 TANK Fig 3 b...

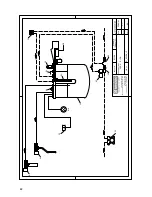

Page 10: ...10 4 mod S1 TANK 3 A B C D E 6 5 7 mod E1 S1 mod S1 TANK 1 2 2 8 8 9 1 Fig 6...

Page 11: ...11 1 2 A B C Fig 7 Fig 8 Fig 9 Fig 10 Fig 11...

Page 12: ...12 1 2 Fig 12 B C 2 1 Fig 13...

Page 35: ......