54

7.3. Starting up

Model S

●

Turn on the water supply tap 2 Fig.6.

●

Turn the main switch 1; the pump is activated,

filling the boiler.

●

When the level has been reached the pump stops,

then activate switch 2 to begin heating the water

in the boiler then turn each one until water begins

to flow from them.

●

Wait for the machine to reach its working pressure,

and to reach the correct thermal balance.

Model E

●

Turn on the water supply tap 2 Fig.6.

●

Turn on main switch 1 and resistance switch 2.

The pump for boiler filling will activate (red led on

level indicator 9).

●

Only after reaching the level (green led on level

indicator 9) the resistances for water heating in

the boiler are powered,then activate every single

group until water comes out.

●

During the heating phase the leds of the keys

switch on in sequence from left to right until the

working pressure is reached.

Only when the rated pressure is reached it is

possible to adjust the doses.

Warning!

This sequence will be repeated at

every switching on.

7.2. Control instruments

(Fig.7)

Gauge

with mobile needle on a fixed dial with a

double scale.

Visual control of the pump (lower manometer ) and

of the boiler pressure (upper manometer) (mod.

E-S).

Minimum and maximum water

level indicator .

Visual control of water level in boiler (green

Led).

10 Cup-heater switch

(optional).

Two-position switch with led.

By turning on the switch (led on), the cup heating

resistance is power supplied.

8. USE

The machine has a top shelf on which the cups are

kept and heated, ready for use.

This is very important to obtain good coffee as the

pre-warmed cup stops the coffee from growing cold

too quickly.

8.1. Preparing coffee

●

Unclamp the filter-holder from the dispensing unit

and knock any grouts out into the drawer espe

-

cially provided for this purpose, taking care not to

damage the rim of the filter.

●

Use the filter for 1 or 2 coffees, according to

need.

●

Fill the filter with the measure of coffee, level it off

and press it down gently with the presser.

●

Remove any ground coffee that has stuck to the

rim of the filter while pressing.

If ground coffee is left on the rim of the filter, a

leaktight seal is not ensured, with consequent

leaking of water and coffee grounds.

●

Lock the filter-holder into the dispensing unit firmly

to obtain a leaktight seal.

●

Place the cups under the spouts and start pouring

using control 3 or button panel 4 according to

model (Fig.7).

●

When the coffee has been poured, leave the filter-

holder attached to the dispensing unit until the next

coffee is required.

When pouring, beware of the hot parts of the

machine, especially the coffee dispensing

units, the steam and hot water spouts. Do not

put your hands for any reason under the units

and the spouts when they are operating

.

The grinding of the coffee beans is of fundamental

importance to the making of good coffee, and the

granular texture of the resulting grounds should

be such that it takes 25-30 seconds to produce the

beverage. if the coffee is ground too coardsely the

coffee will be pale in colour and weak in flavour, with

only a very small amount of white cream, and if the

grounds are too fine, the coffee will be dark with no

cream. Good coffee can only be made if the beans

are freshly and uniformly ground (only possible when

the blades of the coffee grinder are sharp) and are

then measured out into the correct quantities (rou-

ghly 6 grams per measure). For a correct use, set

the boiler at 1 bar.

The importance of freshly ground coffee beans is

due to the fact that once ground, they rapidly lose

their aromatic qualities, and fats present in the beans

go rancid.

Summary of Contents for EPOCA E

Page 4: ......

Page 6: ......

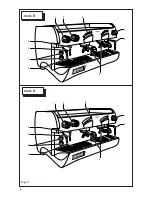

Page 8: ... 2 1 6 3 1 5 2 9 8 4 Fig 3 2 1 6 3 1 5 2 9 8 4 mod S mod E ...

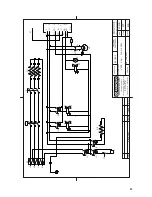

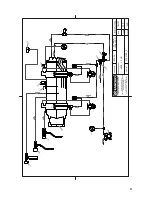

Page 9: ... H D C B A Fig 4 Fig 5 12 11 10 7 4 L o v a t o L 2 3 8 G 1 Ø30mm Fig 6 ...

Page 10: ...10 Fig 7 6 8 9 5 A B C D E 7 10 1 2 4 3 mod S mod E ...

Page 11: ...11 Fig 8 Fig 9 Fig 10 Fig 11 1 1 2 3 ...

Page 33: ......

Page 34: ......

Page 35: ......