61

3. TECHNICAL DATA

3.1. Dimensions and weights

2.2. Machine equipment

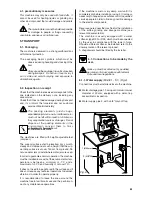

2.3. Mechanical protective devices

The machine is equipped with the following protective

devices:

●

complete panelling protection of all the parts

subject to heat and of the steam and hot water

supplier;

●

work surface provided with grill and tray to collect

spilt liquids;

●

expansion valve in the hydraulic system and valve

on the boiler to avoid overpressure;

●

nonreturn valve on the hydraulic system to avoid

flowing back to the main supply.

2.4. Electric safety devices

The safety devices provided are:

●

5V low tension push buttons an the E1 control key

panel;

●

thermal protection on the pump motor;

●

safe resistance thermal.

2.5. Aerial noise

Noise level in the working place does not usually

exceed 70dB(A).

2.6. Vibrations

The machine is supplied with rubber vibration

damping feet. In normal working conditions, the

machine does not produce vibrations harmful to the

operator and the environment.

MOD. E1-S1

MOD. S1 TANK

1 dose filter holder

1

1

2 dose filter holder

1

1

Filters

2

2

Disk for cleaning

1

1

1 mt. supply pipe

1

-

1,5 mt. supply pipe

1

-

1,5 mt. drainage pipe

1

-

Pipe connections

1

1

Doser and presser

1

1

Instruction manual

1

1

Brush

1

1

MOD. E1-S1

MOD. S1 TANK

A mm

385

385

B mm

355

355

C mm

565

565

D mm

400

400

H mm

485

485

Boiler capacity in litr.

3,9

3,9

Litres water in tankt

-

2

Machine weight kg

35

28

Water inlet

3/8"

-

Ømm drainage

30

-

Packaging

Volume m

3

0,196

0,196

Dimension LxPxH mm

495x690x575

495x690x575

Gross weight kg

40

33

Summary of Contents for Epoca S

Page 1: ...epoca USE AND MAINTENANCE S CD DE version 2 0...

Page 5: ...2 1 Specifications and composition Fig 3 4...

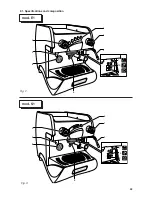

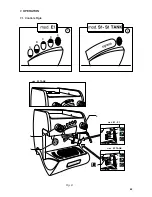

Page 11: ...7 OPERATION 7 1 Controls Fig 8 Fig 8 10...

Page 17: ...epoca PARTS BREAKDOWN CD DE version 1 01...

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

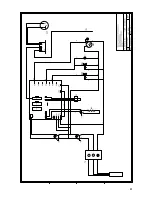

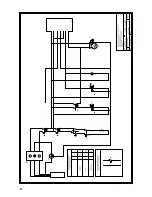

Page 32: ...epoca DIAGRAMS S CD DE version 1 01...

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

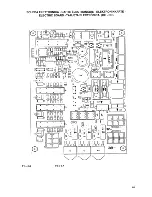

Page 65: ...91 REV 00 J5 J6 J4 GR...

Page 66: ...92...

Page 67: ...93...

Page 70: ...96 EPOCA E1...

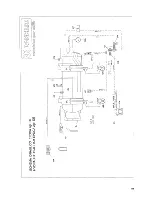

Page 71: ...97 PV EPOCA S1...

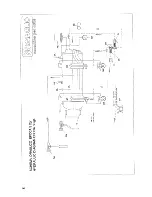

Page 72: ...98 EPOCA S1 TANK...