STILE_05.2022

STILE_05.2022

23 / 28

22 / 28

STILE

STILE

EN

EN

STILE

STILE

EN

EN

Fault

Cause

Solution

Grinding takes

a long time (the

correct amount

of co

ff

ee is not

ground in the time

set for the single

or double dose).

Dirty grinders

• Thoroughly clean the grinders (see section

5.1.3)

Worn grinders

• Have the grinders replaced by quali

fi

ed

technician (see section 5.1.5).

The motor stops

during grinding.

Intervention

of the motor’s

thermal overload

protection due

to hard foreign

bodies between

the grinders

blocking the

system.

• Switch

o

ff

the appliance and wait for the

motor to cool down.

• Disconnect the appliance from the power

supply.

• Extract the shutter and remove the feed

hopper.

• Clean the grinders and remove any foreign

bodies.

• Reassemble the appliance and start a new

grinding cycle.

WARNING!

If the problem persists even after carrying out the suggested

corrective actions, or if functional anomalies other than those shown in the

table occur, contact your local dealer who will decide whether to contact the

RANCILIO GROUP S.p.A. assistance service or to entrust repair or overhaul of

the appliance to a specialised technician.

.

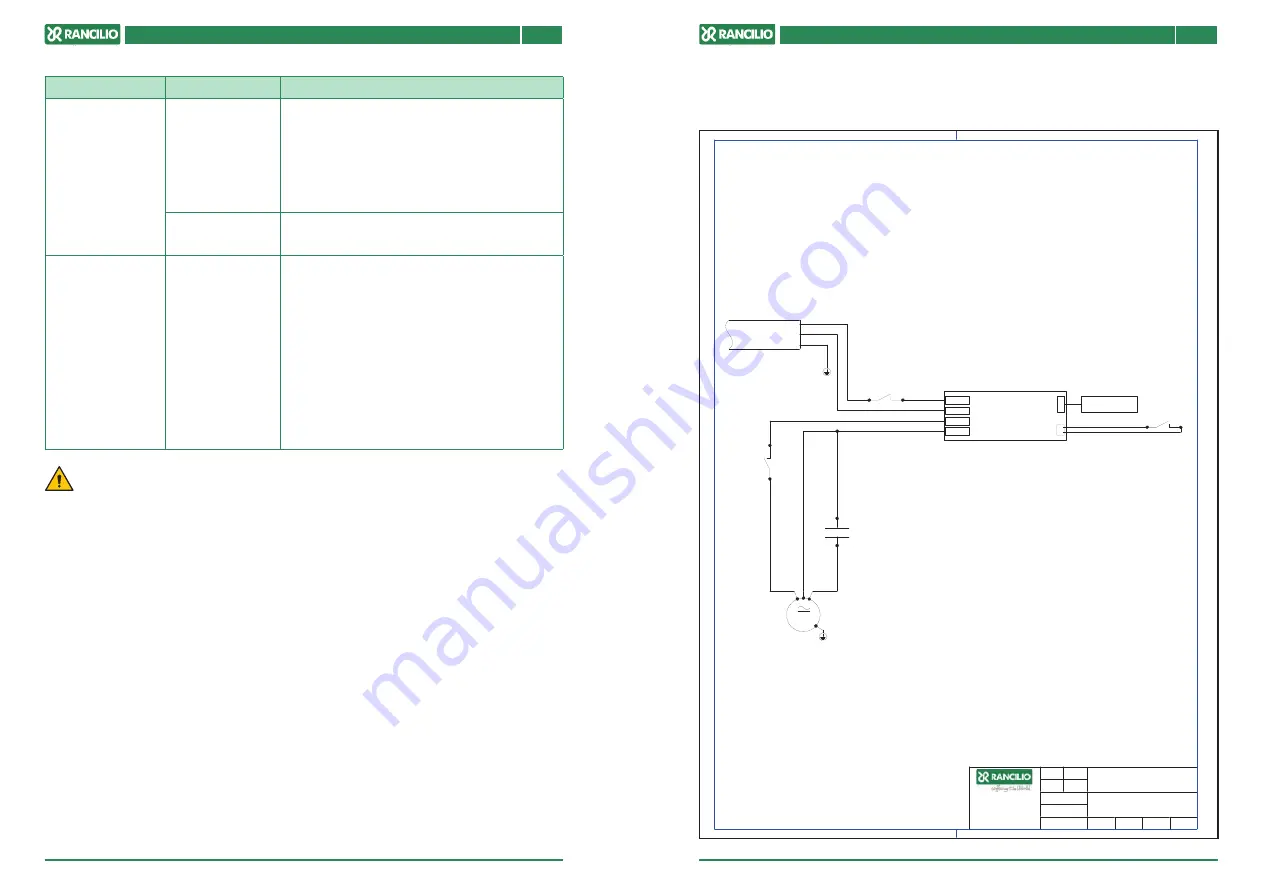

7 ATTACHMENTS

7.1 Wiring diagram

(0(662

$OOSURSULHWDU\ULJKWVUHVHUYHGE\5DQFLOLR*URXS6S$

7KLVGUDZLQJVKDOOQRWEHUHSURGXFHGRULQDQ\ZD\XWLOL]HGIRUWKH

PDQXIDFWXUHRIWKHFRPSRQHQWRUXQLWKHUHLQLOOXVWUDWHGDQGPXVW

QRWEHUHOHDVHGWRRWKHUSDUWLHVZLWKRXWZULWWHQFRQVHQW

$Q\LQIULQJHPHQWZLOOEHOHJDOO\SXUVXHG

6+((7

RI

6,=(

/$67,668('$7(

5(9

$

1(:

'5$:,1*1$0(

(OHWULFGLDJUDP

':*67$786

':*180%(5

352-(&7

6HB

67,/(

'5$)7(5

&+(&.(5

&7,

'$7(

87

87

9LDOHGHOOD5HSXEEOLFD

9LOODVWDQ]DGL3DUDELDJR0L

,WDOLD

7HO

)D[

ZZZUDQFLOLRJURXSFRP

LQIR#UDQFLOLRJURXSFRP

32:(56833/<

)6

)6

)6

)6

6

0DLQ6ZLWFK

0

&

-

-

3RZHU%RDUG

6

*ULQG6ZLWFK

'LVSOD\

9+]

6

6DIHW\6ZLWFK