STILE_05.2022

STILE_05.2022

7 / 28

6 / 28

STILE

STILE

EN

EN

STILE

STILE

EN

EN

2

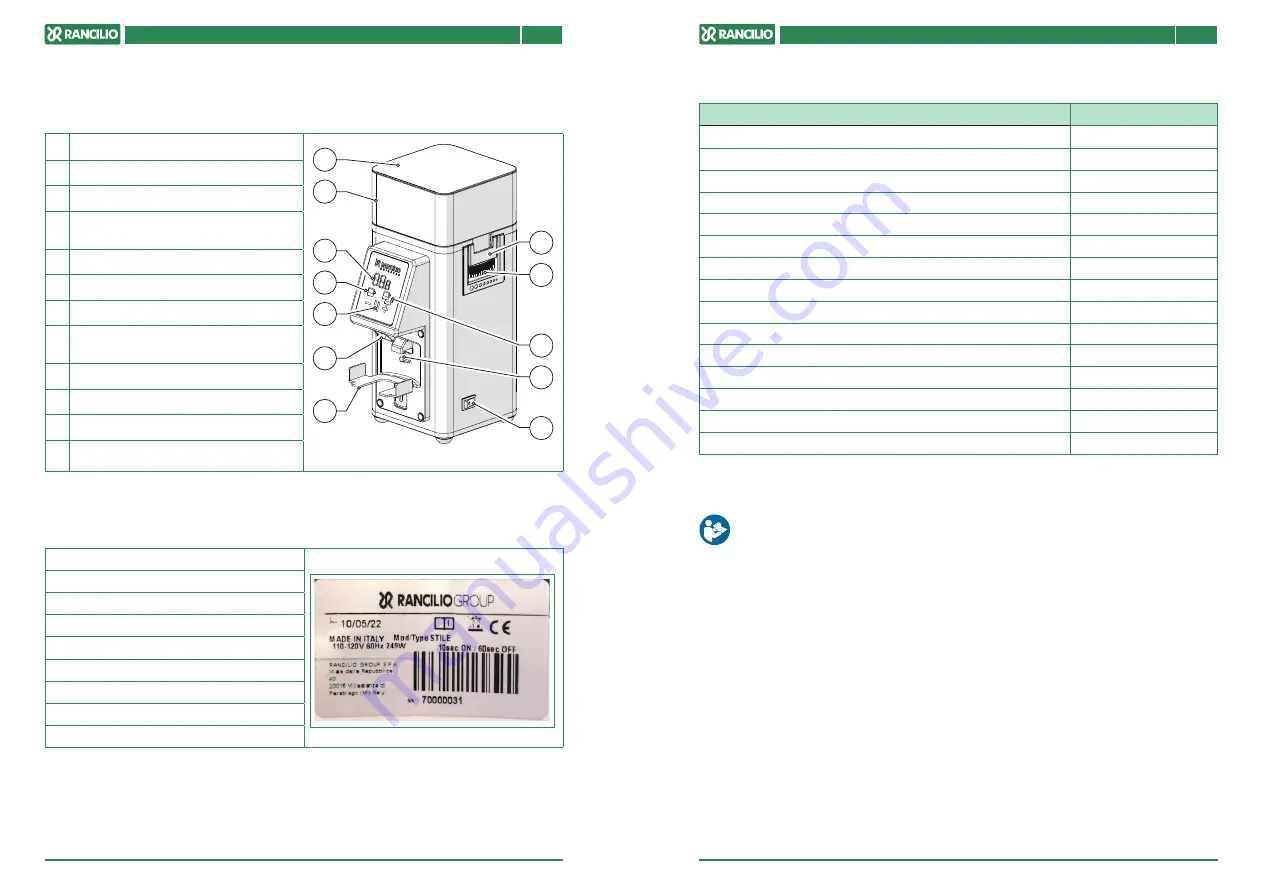

IDENTIFICATION OF THE APPLIANCE AND TECHNICAL DATA

2.1 Identi

fi

cation of the parts of the doser grinder

1 Lid of the hopper

1

0

1

5

2

6

10

8

11

4

9

7

12

3

Fig. 1 - Identi

fi

cation of the parts

2 Co

ff

ee bean hopper

3 Hopper shutter

4 Grinding degree adjustment ring

5 Grinding time display

6 Single Dose Button

7 Double Dose Button

8

Micro SW (active only in

"Preselection" mode)

9 Porta

fi

lter button

10 Ground co

ff

ee outlet

11 Fork for porta

fi

lter

12 Main switch

2.2 Identi

fi

cation of the appliance

An identi

fi

cation label on the appliance bears the following data:

Manufacturer brand

Date of manufacture

Symbols and markings

Country of manufacture

Model

Voltage, Frequency, Duty cycle and Power

Manufacturer's address

Barcode

Serial number

2.3 Technical details

Doser grinder

STILE

Power supply (EUROPE market)

220-240V 50-60 Hz

Power supply (USA-CANADA market)

110-120V 60 Hz

Power [Watt@110-120V / Watt@220-240V]

249 / 190

Duty cycle @110-120V, 60Hz [ON / OFF ]

8 sec. / 200 sec.

Dimensions of appliance (L x W x H) [mm]

132 x 185 x 315

Net weight [kg]

5.5

Hopper capacity [kg]

0.3

Single dose grinding time [s]

6-7

Double dose grinding time [s]

11-12

Custom grinding time (manual) [s]

20

Grinding time tolerance [s]

± 0.1

Daily grinding [kg]

1-2

Single dose dispensing time recommended for 7g [s]

5

Double dose dispensing time recommended for 14g [s]

10

Noise [dB (A)] (with appliance in operation)

69

2.4 Safety devices of the doser grinder

All doser grinders RANCILIO GROUP S.p.A. are equipped with mechanical and

electromechanical devices designed to ensure the safety of the user and the

integrity/functionality of the appliance during its use.

In particular, the

STILE

doser grinder is equipped with the following safety devices:

•

Motor thermal overload protection

The motor of the appliance has thermal overload protection which cuts out the power

supply to the motor itself in the event of overcurrent or overheating.

•

Anti-intrusion button in co

ff

ee loading hopper (Fig. 2)

The anti-intrusion button (detail 2) inside the feed hopper (detail 1) allows co

ff

ee

beans to enter the grinding chamber while preventing the operator from accidentally

inserting his or her

fi

ngers.

•

Co

ff

ee loading hopper microswitch (Fig. 3)

A microswitch (detail 1), located inside the body of the appliance, allows the

appliance to be started only when the co

ff

ee loading hopper (Fig. 2 detail 1) is in the

correct working position. Removing the hopper instantly deactivates the microswitch,

stopping the grinding motor.