R

andall

UnIOn

l

Ock

-S

tItch

Thread / Needles & Awls

R

andall

UnIOn

l

Ock

-S

tItch

Since 1858

technical Support

1-800-327-9420

4

S

eTTINg

T

he

N

eedLe

1) Make sure that the needle is put into the nee-

dle bar (Ul-210) as deeply as possible, then

tighten the needle bar screws in place.

2) Insure that the hook of the needle is looking

directly at the operator.

S

IzeS

OF

N

eedLeS

TO

T

hReAd

Sizes will vary between applications.

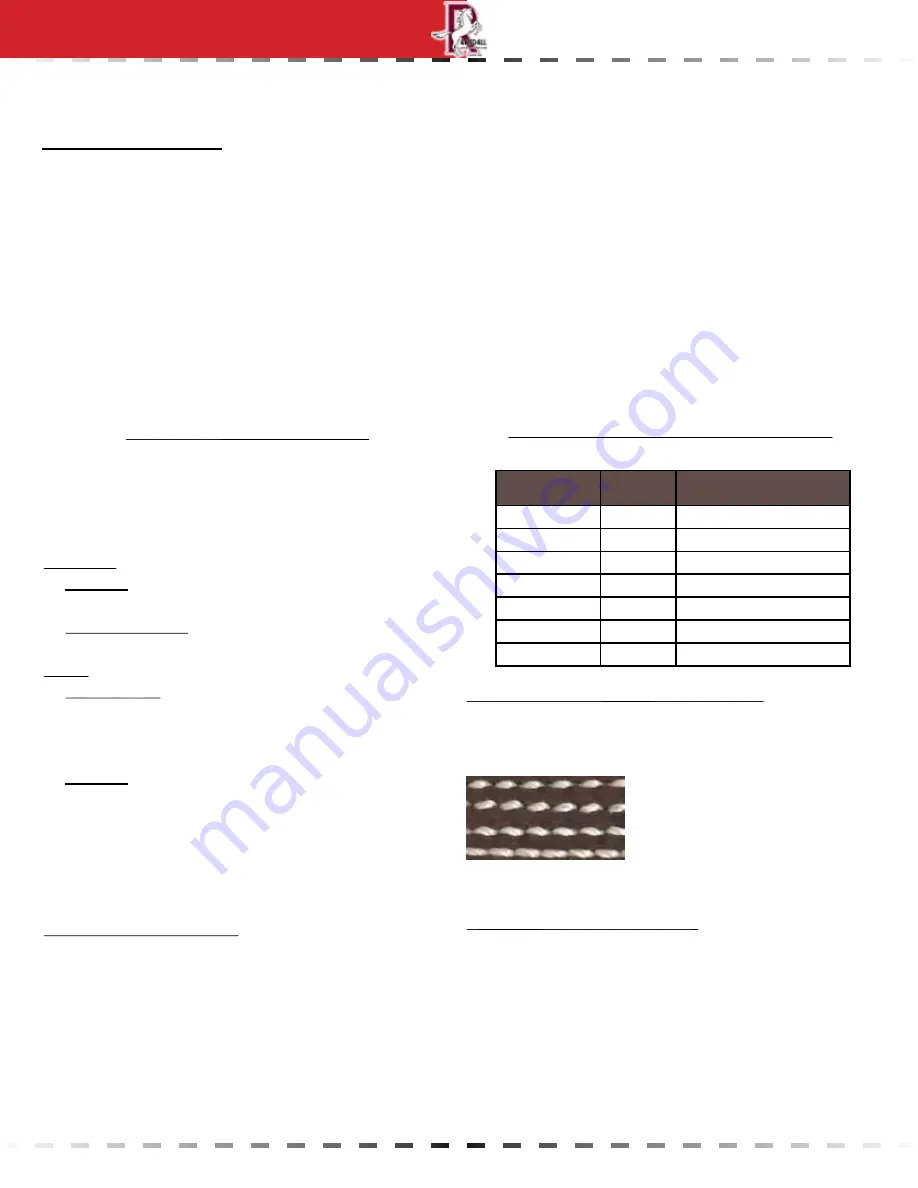

Appearance of Chisel Point Awl:

Turning the

awl so the edge of the blade will start its cut in a

different position can change the appearance of

the stitch.

Awl parallel to Stitch line

Awl Angled left

Awl Angled right

Awl perpendicular to Stitch line

NeedLeS & AwLS

orders for needles and awls must specify the

quantity required, the size number, and also class

and variety. The following is an example of an

order with sufficient information: “100 UNION #2

Awls, chisel point”

Needles

•

NOTE:

The needle size is determined by the

size of the thread you sewing with.

•

Needle Sizes:

1, 1 ½, 2, 2 ½, 3, 3 ½, & 4.

Awls

•

Awl Sizes:

2, 2 ½, 3, 3 ½, 4, & 5

• Chisel Point Awl – harness or straight work.

• Oval Point Awl – boot siding, vamp closing &

belts.

•

NOTE:

The awl size should be 1 to 1-1/2 sizes

larger than the size of the needle.

Make sure

that the awl is sharp and does not spring or

glance off the work when entering the work.

Synthetic

Twisted

Natural

Cord

Needle Size

138

3 cord

1 to 1-1/2

207

4 cord

1-1/2 to 2

277

5 cord

2-1/2 to 3

346

6 cord

3 to 3-1/2

415

7 cord

4 to 4-1/2

554

8 cord

4-1/2

693

9 cord

5

S

eTTINg

The

A

wL

1.

Turn the hand wheel so that awl bar (Ul-85)

is at its highest position. loosen the awl set

screw and remove the old awl

2.

Insert the awl into the awl bar as far as it will

go. Set point in desired position. It is common

to have the point set a little to the right of

being squared across

3.

Tighten set screw in awl bar

S

ewINg

T

hReAd

• The UNION can use thread size 138 to 554 synthetic or 3 to 12 cord cotton or linen

• Use only

Left Twist

thread in the machine (twist of the bobbin thread is not important). To determine

the thread twist, hold the thread and twist it counterclockwise between the thumb and forefinger. If the

strands wind tighter, the thread is left (Z) twist. If the strands unwind, the thread is right (S) twist.

• If you are using a natural thread, wither linen or cotton, the label end of the spool of the thread must

be pointed up when placed in the thread holder. The bobbin thread should be one size smaller than

the top thread for a better lock. Make sure that the thread is not old, dry, or right twist.

• If you use a larger thread with an undersized needle, skipped stitches or frayed thread may occur.