4

OM-SIDE MOUNT WORK TOP REFRIGERATOR

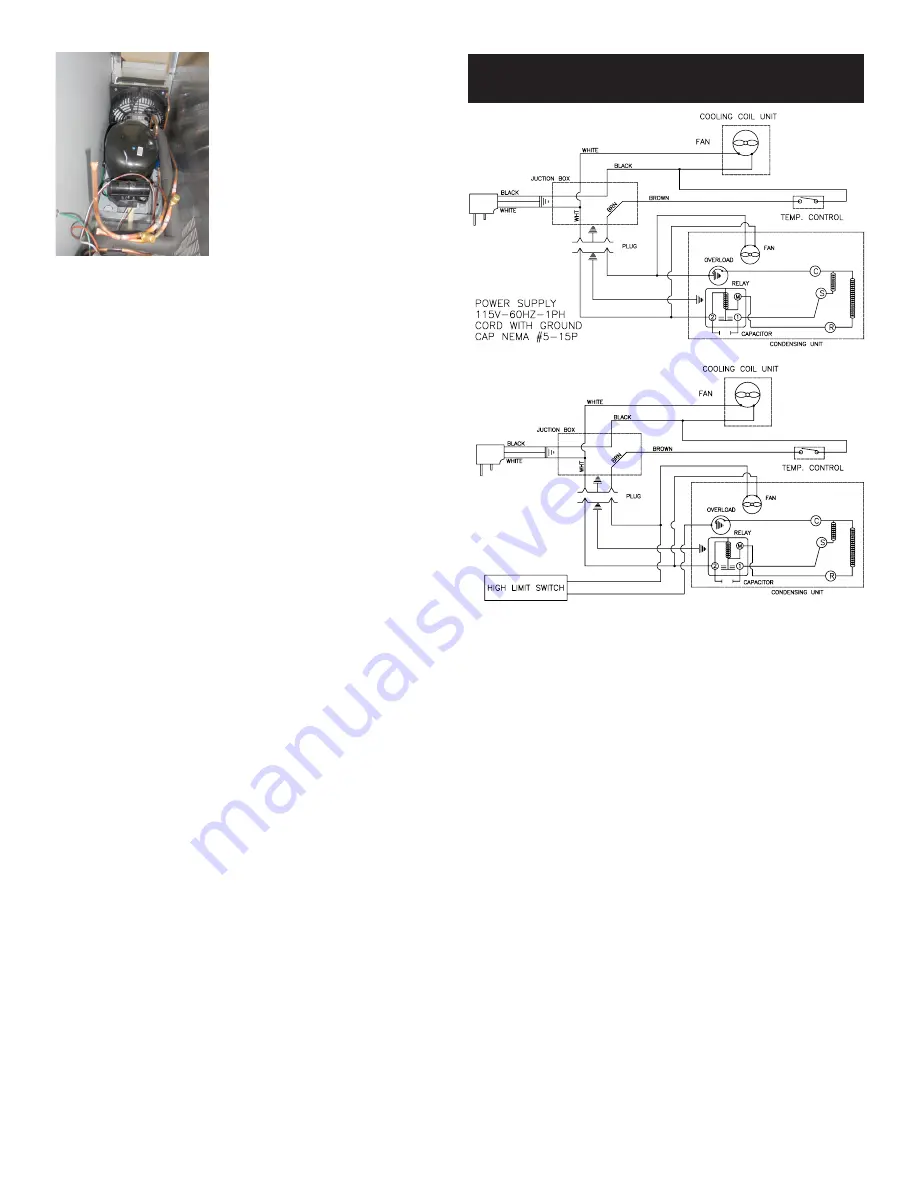

Wiring Diagram

the blade to the motor shaft and pull the blade

off the shaft. Install a new fan blade, replacing

any washers, and tighten the retaining nut. To

test the condenser fan motor, disconnect the

wires to the fan motor. Using a multimeter set

at RX10, touch one probe to each terminal. The

multimeter needle should show approximately

45 to 50 ohms resistance. A lower reading

indicates the motor is faulty and needs to be

replaced.

Next, set the multimeter at RX1000 and touch

one probe to the motor terminals and the other

probe to any unpainted metal part of the unit.

If the multimeter needle moves, the motor is

grounded and needs to be replaced. To remove the motor, unscrew the bracket

that holds the fan motor to its housing. Slide the motor out of the housing. Remove

the fan blade from the old motor and attach to the new motor, replacing any

washers. Install the new motor in its housing by screwing the bracket into place.

Reattach the wires to the motor terminals and reconnect the ground wire.

SERVICING THE COMPRESSOR

The compressor is part of the sealed refrigeration system and should be replaced

by a professional service technician. You can, however, test the compressor and

certain components. Prior to testing, unplug the unit and remove the access cover

to the mechanical housing. A small box mounted on the side of the compressor

protects the relay, overload protector, and capacitor. Release the wire retaining clip

that holds the cover in place and slip off the cover and the clip.

To test the compressor relay, pull the relay straight off the compressor without

twisting or damaging it. If the relay has an external wire coil, hold the relay so

that the word TOP is up. Using a multimeter set at RX1, place the probes on

terminals S and M. The multimeter needle should not move. Remove the probe

from terminal M and place it on the side terminal marked L. The multimeter needle

should not move. Remove the probe from terminal S and place it on terminal M.

The multimeter needle should sweep across the scale, indicating full continuity.

Turn the relay upside down. Using a multimeter set at RX1, place the probes

on terminals S and M. The multimeter needle should sweep across the scale,

indicating full continuity. Remove the probe from terminal M and place it on the

side terminal marked L. The multimeter needle should sweep across the scale,

indicating fully continuity. Remove the probe from terminal S and place it on

terminal M. The multimeter needle should not move.

If the relay fails any of the tests listed above, the relay is faulty and needs to

be replaced. Push a new relay onto the compressor terminals and replace the

terminal cover. If the relay passes all the tests listed above, proceed to testing of

the overload protector.

To remove the overload protector, use a screwdriver to gently pry open the circular

spring clip that secures the overload protector to the compressor and snap out

the overload protector. Pull the two wire connectors off the terminals. Using a

multimeter set at RX1, touch a probe to each overload protector terminal. The

multimeter needle should sweep across the scale, indicating full continuity. If the

overload protector passes this test, proceed to testing of the compressor. If the

overload protector fails this test, the overload protector is faulty and needs to be

replaced. Reattach the push-on connectors to the new overload protector, clip it in

place on the compressor, and replace the terminal cover.

For testing the compressor, use a multimeter set at RX1 to test each of the three

terminal pins against each of the other two terminal pins. Each pair should show

continuity. Then, with the multimeter set at RX1000, place one probe against the

metal housing of the compressor (if necessary, scrape off a small amount of paint

to ensure contact with bare metal). Place the other probe on each of the three

terminals in turn. If any of the three terminals shows continuity with the housing,

the compressor is grounded. If the compressor fails either test, call for service

at 888-994-7636. If the compressor passes the tests, reinstall the overload

protector, relay, terminal cover, and mechanical housing cover.