13

Randell has attempted to preset the cold control to ensure that your unit runs at an opti-

mum temperature, but due to varying ambient conditions, including elevation, food prod-

uct as well as type of operation you may need to alter this temperature. Additional adjust-

ments can be made (within limits) by turning the control dial up or down until the desired

temperature is reached. Control dial is located next to the compressor (See figure A).

1. Unit Cleaning may be performed at this time.

2. Turn on unit.

3. Allow 45 minutes to one hour for your unit to cool down before loading product.

4. Load the product and proceed with food preparation.

1. Remove product from unit at the end of the day’s preparation.

2. Turn off unit.

3. Unit cleaning maybe performed at this time if the frost has melted off the surface.

Randell strongly suggests a preventive maintenance program which would include the

following

Monthly

procedures:

1. Cleaning of all condenser coils. Condenser coils are a critical component in the life of

the compressor and must remain clean to assure proper air flow and heat transfer. Failure

to maintain this heat transfer will affect unit performance and eventually destroy the

compressor. Clean the condenser coils with coil cleaner and/or a vacuum, cleaner and

brush.

NOTE: Brush coil in direction of fins, normally vertically as to not damage or

restrict air flow from passing through condenser.

2. Clean fan blade on the condensing.

3. Clean and disinfect drains with a solution of warm water and bleach.

NOTE: DO NOT USE SHARP UTENSILS

Reference: Nickel Development Institute, Diversey Lever, Savin,

Ecolab, NAFEM

Do not use steel pads, wire brushes, scrapers or chloride cleaners to clean

your stainless steel.

UNIT OPERATION

MORNING STARTUP

EVENING SHUT DOWN

PREVENTIVE MAINTENANCE

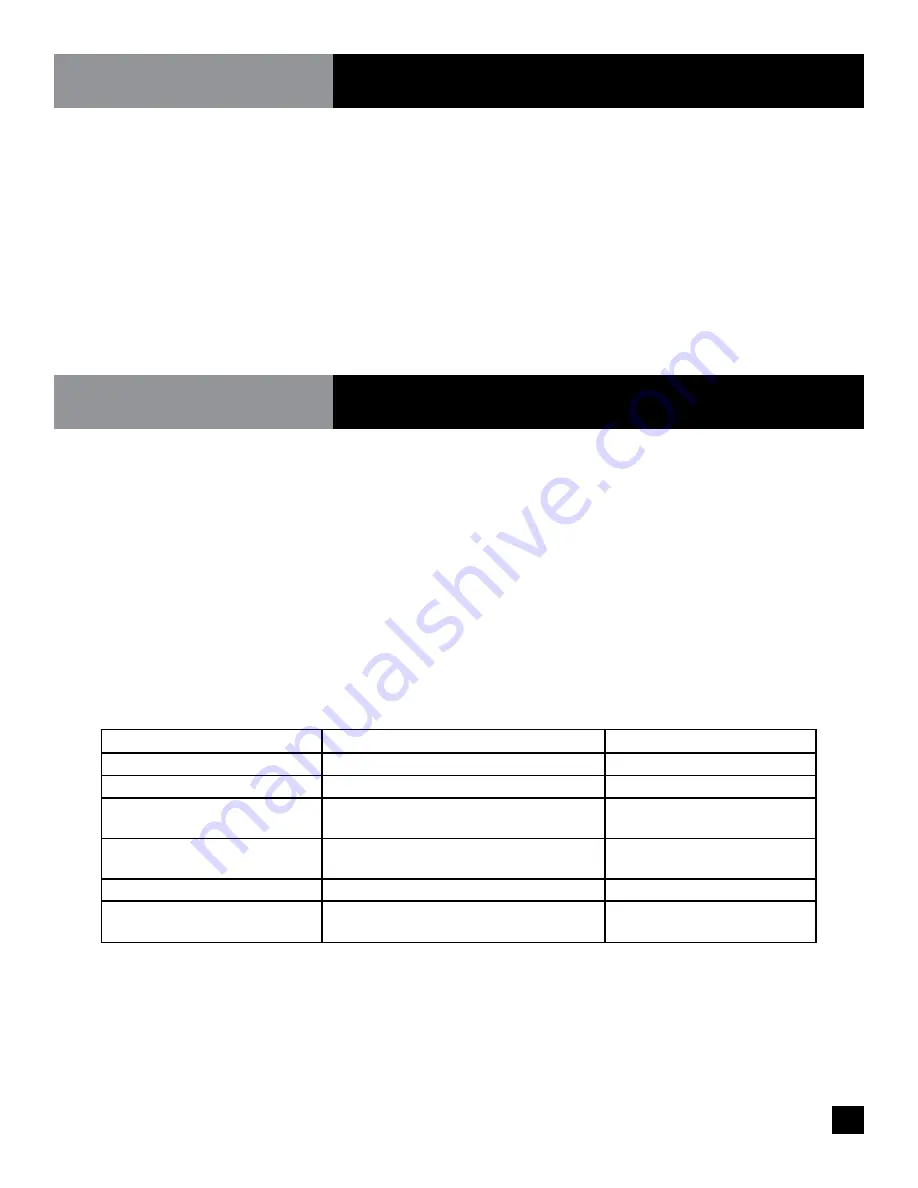

JOB

CLEANING AGENT

COMMENTS

Routine cleaning

Soap, ammonia, detergent Medallion

Apply with a sponge or cloth

Fingerprints and smears

Arcal 20, Lac-O-Nu, Ecoshine

Provides a barrier film

Stubborn stains and discoloration

Cameo, Talc, Zud, First Impression

Rub in the direction of the

polish lines

Greasy and fatty acids,

blood, burnt-on foods

Easy-Off, Degrease It, Oven Aid

Excellent removal on all

finishes

Grease and Oil

Any good commercial detergent

Apply with a sponge or cloth

Restoration/Passivation

Benefit, Super Sheen,

Good idea monthly

randell.com