LM05 SERIES II I&M MANUAL/EN/11.30.2010

28/89

This document and the information contained herein, is the exclusive property of R&M Materials Handling, Inc., and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling, Inc.

Copyright © (2010) R&M Materials Handling, Inc. All rights reserved.

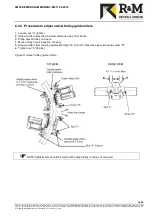

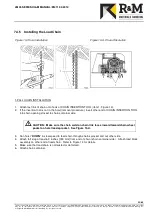

7.3.3 Hoist Motor Brake Adjustment (See

Figure 11

)

If maximum air gap of brake has been reached or will be exceeded before next inspection, readjust air gap.

Minimum air gap

Maximum air gap

X = 0.008” [ 0.2 mm ]

X = 0.020” [ 0.5 mm ]

Before adjusting brake, remove load. Per ANSI Z244.1, lockout and tag main disconnect switch in de-

energized position. Follow other maintenance procedures outlined in this manual and ASME B30.16.

1. Remove brake cover and gasket.

2. With a feeler gauge, check three (3) places near each mounting bolts to measure air gap ( X )

between brake thrust disc (item 2) and coil (item 1).

3. To adjust air gap use a 0.008” feeler gauge and proceed as follows:

Loosen locking screw (item 5).

Adjust the air gap by turning the brake adjusting nut (6) counterclockwise to reduce the air gap;

turn clockwise to increase it.

Tighten the locking screw (5).

Make the same operation with the 2 other adjustment points.

Control the air gap adjustment all around the magnet.

4. Check brake operation. Run load block up and down several times without a load to test operation

of brake. Then, lift a capacity load about one foot above floor, stop, and check that brake holds

load.

5. Install gasket and brake cover.