R&M Materials Handling, Inc

STAGEMAKER

®

Concert Hoist

Springfield, Ohio USA

Technical Guide

:

800 955-9967

June 2009

www.rmhoist.com

RM-STGMKR-TG-2002-6-ENG.doc

51

®

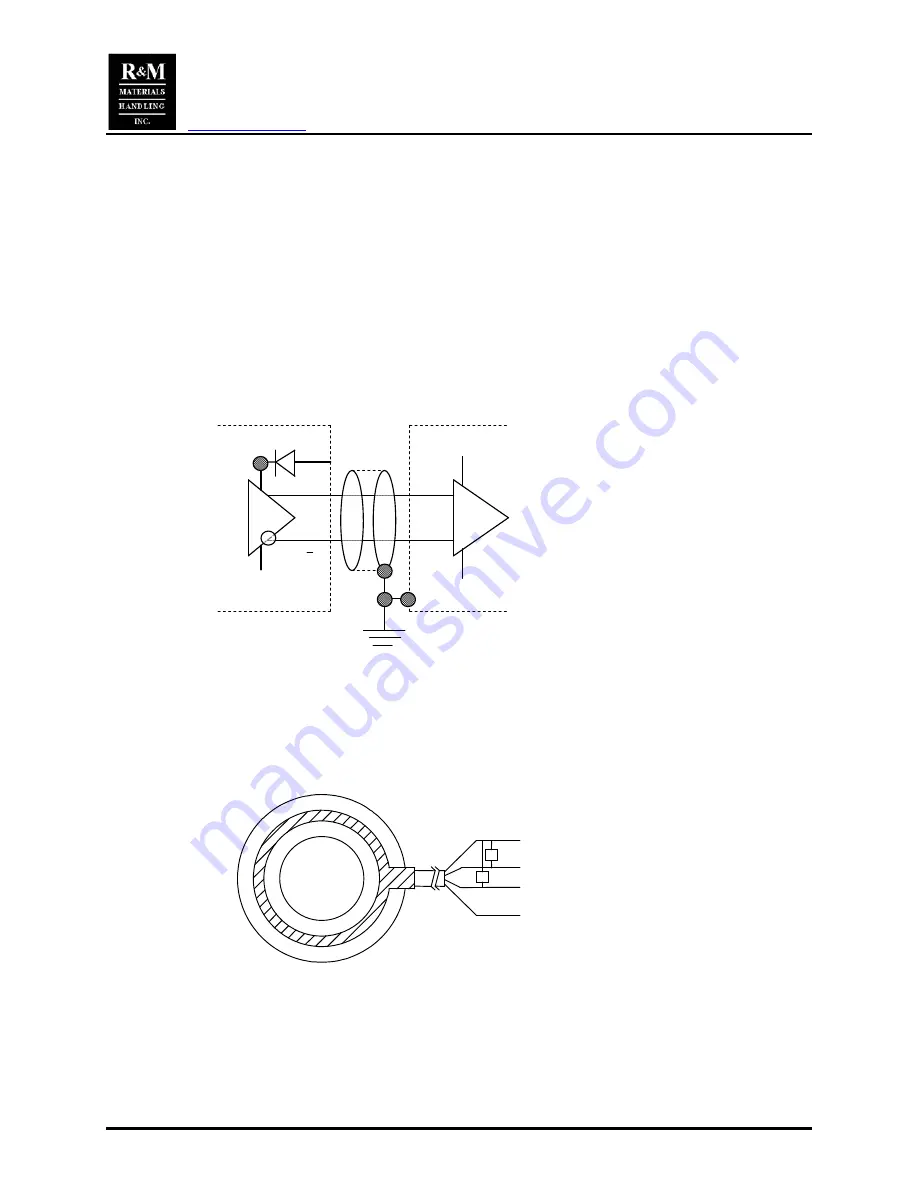

17 Incremental Encoder

The incremental encoder constantly monitors the position/height of the load and feeds it back to the

controller. With the incremental encoder, the positions are not absolute and need to be reset.

Note:

None of these encoders are short-circuited protected. Therefore, it is very important to check the

wiring before power is applied. R&M recommends the use of Belden MMICS shielded cable for the motor

cables when an incremental encoder is used.

17.1 SM1 Hoists

The encoder when supplied on the SM1 hoist is mounted next to the brake in the same spot where the

geared limit switch would be mounted. The geared limit switch cannot be furnished if the encoder is

supplied on this hoist. The flange is specially machined and therefore it is not possible to add an encoder

to existing units.

The encoder generates two signals, A and B at 5 pulses per one revolution.

17.2 SM5 or SM10 Hoists

The encoder when supplied on the SM5 or SM10 hoist is a ball bearing with an integrated pulse sensor.

The bearing housing is specially machined and therefore it is not possible to add an encoder to existing

units.

The encoder generates two signals, A and B at 32 or 48 pulses (depends on the hoist size) per one

revolution.

Supply:

3.8<+V<24V

Signal B

Signal A

0V

R

R

1

2

3

4

The required power supply is 24Vdc. Wiring is as follows:

Red wire:

+24Vdc

Black wire:

ground

White wire:

signal A

Blue wire:

signal B

The encoder must be wired through the supplied filter because the encoder is sensitive to induced noise.

The filter does not include the resistors for the 24Vdc.

A

A

OW

11 - 30V

11 – 30V

0V

Wire color identification:

White:

0V

Brown:

+Vcc

Green:

A

Yellow:

B

Gray: Top 0

Pink:

A/

Blue:

B/

Red:0/