24

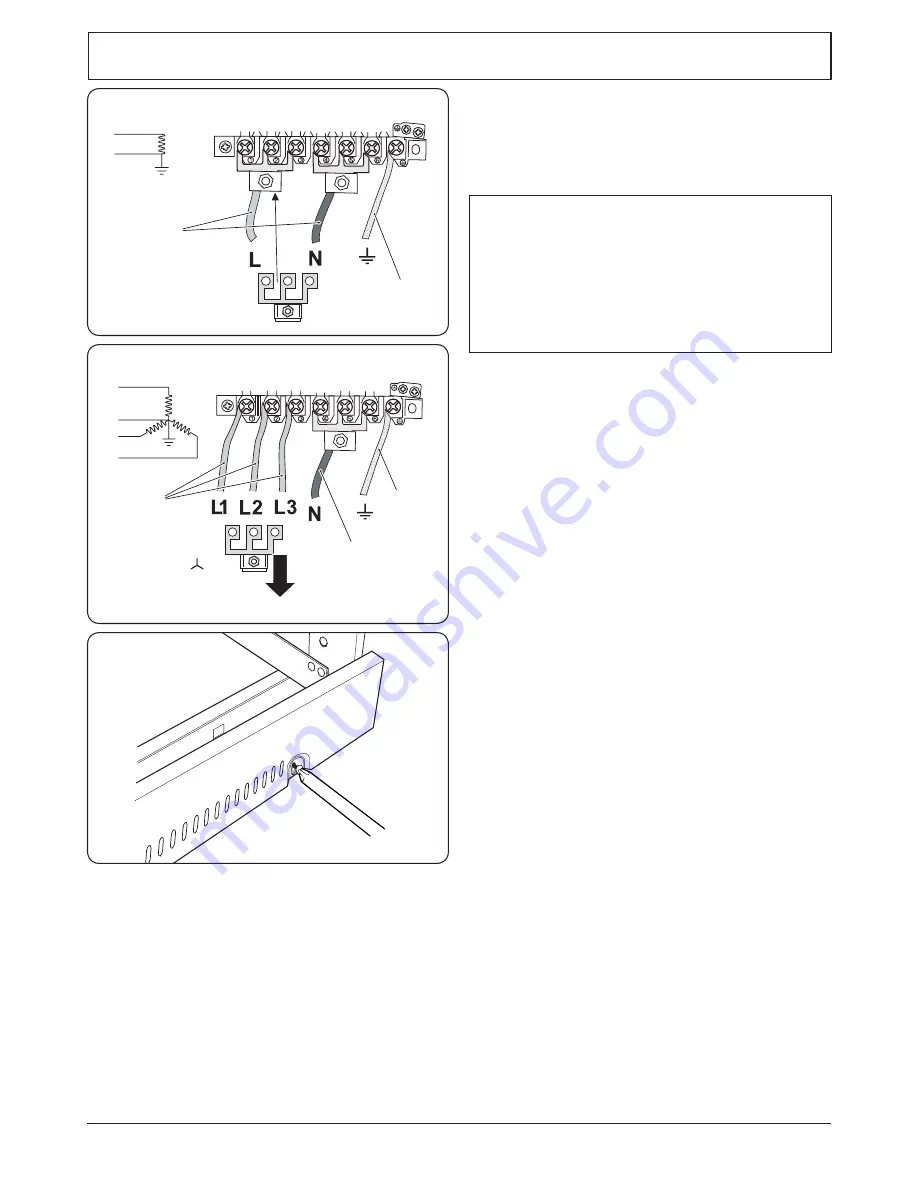

ArtNo.130-0010 Electrical connections single-phase

L

N

230 V ac 50 Hz

10 mm² max

6 mm² max

Electrical Connection

The cooker must be installed by a qualified electrician, in

accordance with all relevant British Standards/Codes of

Practice (in particular BS 7671), or with the relevant national

and local regulations.

Current Operated Earth Leakage Breakers

The combined use of your cooker and other domestic

appliances may cause nuisance tripping, so we

recommend that the cooker is protected on an individual

RCD (Residual Current Device) or RCBO (Residual Current

Breaker with Overload).

IF IN DOUBT, PLEASE CONSULT A SUITABLY QUALIFIED

ELECTRICIAN.

Note:

The cooker must be connected to the correct electrical

supply as stated on the voltage label on the cooker, through

a suitable cooker control unit incorporating a double-pole

switch, having a contact separation of at least 3 mm in all

poles.

n

n

The cooker MUST NOT be connected to an ordinary

domestic power point.

Access to the mains terminal is gained by removing the

electrical terminal cover box on the back panel. Connect

the mains cable to the correct terminals for your electrical

supply type (

Fig.7.15

and

Fig.7.16

). Check that the links are

correctly fitted and that the terminal screws are tight. Secure

the mains cable using the cable clamp.

Final Checks

Hotplate Check

Check each burner in turn (refer to the

‘Hotplate Burners’

section at the front of the instructions).

Grill Check

Turn on the grill control and check that the grill heats up.

Oven Check

Set the clock as described earlier in the instructions, and then

turn on the ovens. Check that the oven fans start to turn and

that the ovens start to heat up.

Note:

The oven light bulb is not included in the guarantee.

Turn off the oven.

Fitting the Plinth

Loosen the 3 screws along the front bottom edge of the

cooker. Hook the central keyhole over the central screw. Twist

and fit each end keyhole over their respective screws.Tighten

the fixing screws

(Fig.7.17)

.

Customer Care

Installer:

Please complete your details in this guide, inform

the user how to operate the cooker and hand over the

instructions.

Thank you.

ArtNo.350-0012 - Securing the plinth

L1

N

L3

L2

3N ac

230/400 V 50 Hz

6 mm² max

10 mm² max

6 mm² max

INSTALLATION

Check the appliance is electrically safe and gas sound when you have finished.

Fig.7.15

Fig.7.16

Fig.7.17