WIRING INSTRUCTIONS

ALL WIRING MUST BE CARRIED OUT IN ACCORDANCE WITH CURRENT IEE WIRING REGULATIONS.

The boiler must be installed by a qualified competent tradesman in accordance with these instructions and drawings to ensure correct operation.

Check the main incoming supply to the property to ensure there is sufficient current and voltage for the size of the boiler or boilers to be installed.

Remember to also take account of the supply requirements for the rest of the property. Ensure the correct cable size is used to feed the boiler.

Ensure the installation complies with current IEE regulations BS7671:2008.

A double pole RCD with a trip level sensitivity of 30mA and capable of breaking the full load current to BS EN 61008:1994, must be used.

In order to provide a means of isolation, the boiler must be connected to the supply through a double pole linked switch with a

minimum contact gap of 3mm in all poles. The RCD is suitable for this requirement if it is mounted in close proximity to the boiler.

A correctly rated MCB must be used in the supply, see Technical Specifications (see page 19). An additional 3A supply is required for

the controls etc. NOTE, a blank must be fitted between each MCB to provide ventilation, check with the MCB manufacturer/supplier.

NOTE:

The high current mains supply

MUST NOT

be routed through the programmer, controls etc. Follow the wiring diagrams. Use a standard

programmer, room thermostat, etc.

The high current switching is carried out inside the boiler, only standard switched live (low current) control signals are supplied by the

programmer etc.

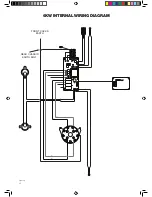

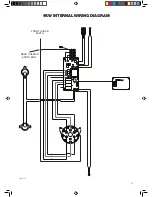

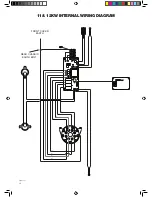

ELECTRICAL CONNECTIONS

Access can be gained to the boielrs electrical connections by removing the front panel. The earth lead is removed from the front cover by depressing

the release button on the connection to the cover.

IT IS IMPORTANT THAT THE EARTH CONNECTION SHALL ALWAYS BE RECONNECTED WITH THE RELEASE BUTTON

FITTED INWARDS AND EARTH BOND TESTED AFTER ANY MAINTENANCE HAS BEEN CARRIED OUT.

THESE CONNECTIONS MUST BE TIGHT. LOOSE CONNECTIONS COULD CAUSE A FIRE OR BURNING AT MAIN TERMINAL

CONNECTOR AND IS NOT COVERED BY THE WARRANTY.

1. MAIN POWER. Main power-supply cables. Using the correct rated cables, connect the main terminals live, neutral and earth directly to the isolation

switch,. Do not connect the power through the programmer, thermostats etc. The main power terminals in the boiler are suitable for cables up to 16mm.

2. CN1: CONTROL SIGNAL. Connect switched live to ‘D’ and neutral to ‘N’ on the control terminal block in the boiler to the switched live and neutral

from the programmer control circuit. A neutral must be connected, as this control signal is optically isolated from the main supply in the boiler and will

not run without a neutral.

3. CN2: PUMP CONNECTIONS. The supply to the pump must be connected to the ‘PUMP’ terminal on the control terminal block in the boiler. This

supply is fused in the boiler at 2A.

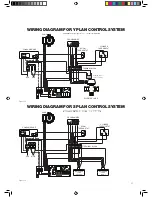

CONNECTIONS FOR 2 OR MORE BOILERS

1. Main power-supply cables. Connect each boiler to its supply live, neutral, and earth, as described above. The supplies to each boiler can be on

different phases if using a 3-phase supply.

2. CN1: Control signal. Join all the boiler ‘D’ terminals on the control terminal block together, and then connect them to the switched live control

signal to the programmer control circuit. Connect all the boiler ‘N’ terminals on the control terminal block together and then to neutral on the

programmer control circuit.

3. CN2: Pump connections. The pump must be connected through a relay assembly to ensure that the pump always operates if any one boiler is

running. Check the main electrical power connections are tight. Loose connections can cause a fire and will invalidate the warranty. The control

DEMAND signal is optically isolated from the main boiler supply to enable different phases to be used between boilers. The control signal required to

operate the boiler is 220v - 240v at a very low current typically 10mA.

12