11

FIG. 13

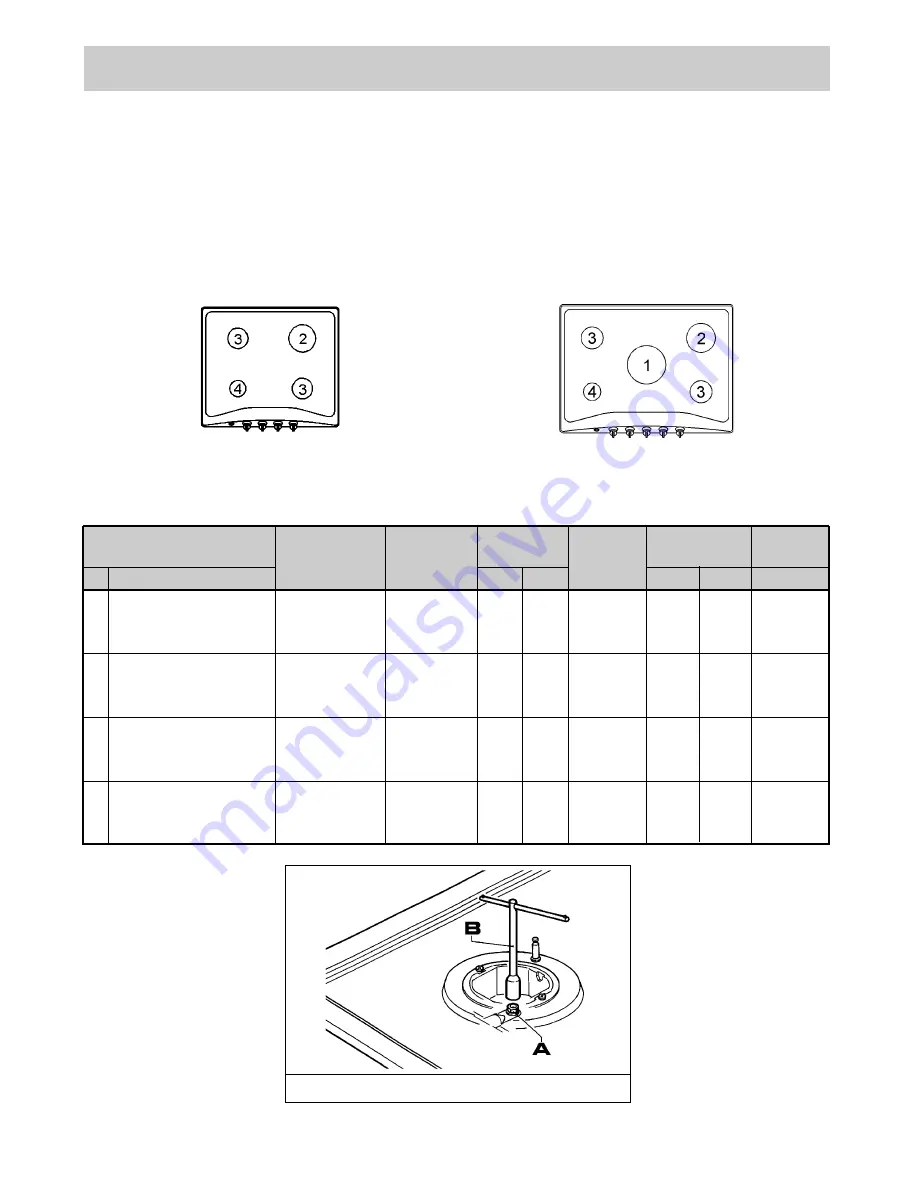

10) REPLACING THE INJECTORS

The burners can be converted to different types of

gas by changing the injectors. To do this, first remove

the burner tops. Unscrew the injector "A" (see fig. 13).

See the table for the correct injector size. Fit the new

injector and screw it down hard.

After the injectors have been replaced, the

burner reduced rate may need to be adjusted

as explained in section 9. Reset any seals on

the regulating or pre-regulating devices.

Table lists the heat inputs of the burners, the

diameter of the injectors and the working pressures

of the various types of gas.

CONVERSIONS

BURNER ARRANGEMENT ON THE HOTPLATE

BUTANE

28 - 30

225

90

1400

3100

62

PROPANE

37

222

90

1400

3100

62

NATURAL

20

295

121 Y

1400

3100

62

BUTANE

28 - 30

204

83

800

2800

45

PROPANE

37

200

83

800

2800

45

NATURAL

20

267

117 S

800

2800

45

BUTANE

28 - 30

127

65

500

1750

35

PROPANE

37

125

65

500

1750

35

NATURAL

20

167

97 Z

500

1750

35

BURNERS

N°

DESCRIPTION

GAS

NORMAL

PRESSURE

NORMAL

RATE

INJECTOR

DIAMETER

NOMINAL HEAT

INPUT (W)

mbar

g/h

L/h

1/100 mm

MIN.

MAX. 1/100 mmm

TABLE

BUTANE

28 - 30

73

50

400

1000

30

PROPANE

37

71

50

400

1000

30

NATURAL

20

95

72 X

400

1000

30

1

ULTRA RAPID

2

RAPID

3

SEMIRAPID

4

AUXILIARY

BY PASS

Summary of Contents for 58580

Page 16: ...16 V I...