INSTALLATION

Check the appliance is electrically safe and gas sound when you have finished.

21

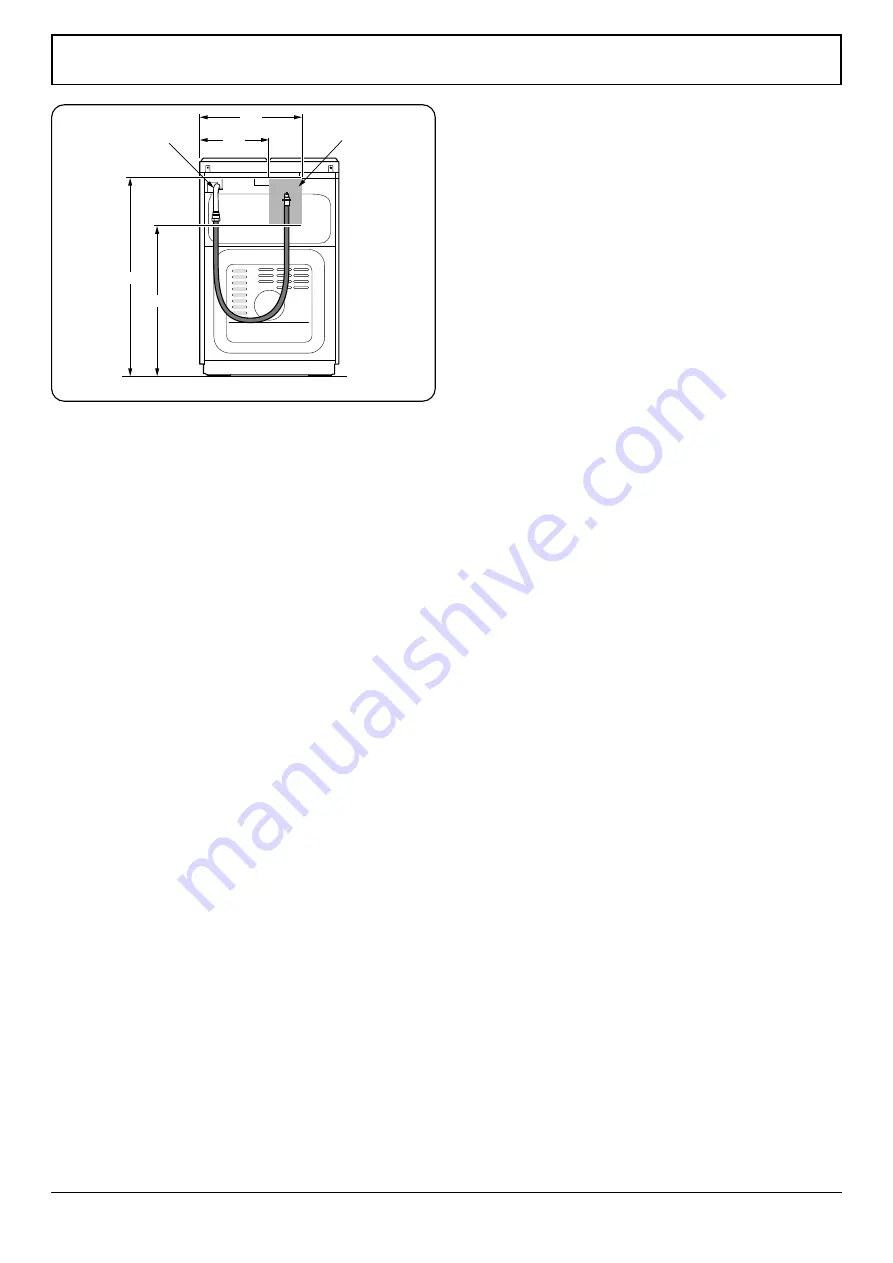

All dimensions in millimetres

800

600

A

400

300

Gas inlet block

Fig. 7.5

Points that must be checked during

fixed gas connection assembly

The method used to assemble a fixed gas connection (gas

connection made by threads, e.g. a nut) varies according

to the country you are in. The most common parts for your

country will be supplied with your appliance. Any other parts

required can be supplied as spare parts.

During connection, always keep the nut on the gas manifold

fixed while rotating the counter-part. Use appropriately-

sized spanners for a safe connection. For surfaces between

different components always use the seals provided in the

gas conversion kit.

The seals used during connection should also be approved

to be used in gas connections. Do not use plumbing seals for

gas connections.

Remember that this appliance is ready to be connected to the

gas supply in the country for which it has been produced.

The main country of destination is marked on the rear cover

of the appliance. If you need to use it in another country, any

of the connections in the figure below may be required. In

such a case, contact local authorities to learn the correct gas

connection.

The Cooker must be installed and maintained by a suitably

qualified gas registered technician in accordance with current

safety legislation.

n

WARNING: Do not use a naked flame to check for gas

leaks.

Electrical Connection

All external wiring must comply with the IEE Regulations

for the Electrical Equipment of Buildings. Connection to the

electrical supply is via a plug and socket.

n

WARNING: The electrical connection of this

appliance should be carried out by an authorised

service person or qualified electrician, according to

the instructions in this guide and in compliance with

the current local regulations.

n

WARNING: THE APPLIANCE MUST BE EARTHED.

•

Before connecting the appliance to the power supply,

the voltage rating of the appliance (stamped on the

appliance identification plate) must be checked for

correspondence to the available mains supply voltage,

and the mains electric wiring should be capable of

handling the appliance’s power rating (also indicated on

the identification plate).

•

During installation, please ensure that isolated cables

are used. An incorrect connection could damage your

appliance. If the mains cable is damaged and needs to

be replaced this should be done by a qualified person.

•

Do not use adaptors, multiple sockets and/or extension

leads.

Summary of Contents for Classic 60 Gas

Page 1: ...Classic 60 Gas Professional 60 Gas User Guide Installation Service Instructions U111323 02a...

Page 2: ......

Page 4: ......

Page 35: ...31 NOTE...

Page 36: ...32 NOTE...

Page 37: ...33 NOTE...

Page 38: ......

Page 39: ......