INSTALLATION

Check the appliance is electrically safe when you have finished.

26

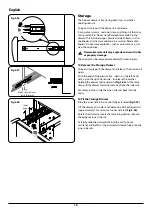

Positioning the Cooker

Fig.8-1

and

Fig.8-2

show the minimum recommended

distance from the cooker to nearby surfaces.

The cooker should not be placed on a base.

Above hotplate surround should be level with, or above, any

adjacent work surface.

A gap of 75 mm should be left between each side of the

cooker

ABOVE

the hotplate level and any adjacent vertical

surface.

For non-combustible surfaces (such as unpainted metal or

ceramic tiles), this can be reduced to 25 mm.

A minimum space of 650 mm is required between the top of

the hotplate and a horizontal combustible surface.

*Any cookerhood should be installed in accordance with

the hood manufacturer’s instructions.

**Any splashback must be fitted in accordance with the

manufacturers instructions. Allowance should be made

for the additional height of the flue trim, which is fitted to

the cooker hob.

Surfaces of furniture and walls at the sides and rear of the

appliance should be heat, splash and steam resistant. Certain

types of vinyl or laminate kitchen furniture are particularly

prone to heat damage and discolouration.

We cannot accept responsibility for damage caused by

normal use of the cooker to any material that de-laminates

or discolours at temperatures less than 65 °C above room

temperature.

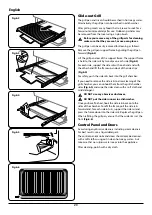

We recommend a gap of 1110 mm between units to allow

for moving the cooker. Do not box the cooker in – it must

be possible to move the cooker in and out for cleaning and

servicing.

A clearance of 130 mm is required if the cooker is near a

corner of the kitchen to allow the oven doors to open

(Fig.8-3)

. The actual opening of the doors is slightly less but

this allows for some protection of your hand as you open the

door.

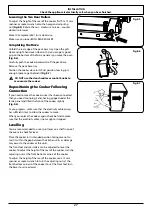

Moving the Cooker

n

n

On no account try and move the cooker while it is

plugged into the electricity supply.

n

n

The cooker is very heavy, so take great care.

We recommend that two people manoeuvre the cooker.

Make sure that the floor covering is firmly fixed, or removed,

to prevent it being disturbed when moving the cooker

around.

To help you, there are two levelling rollers at the back, and

two screw-down levelling feet at the front.

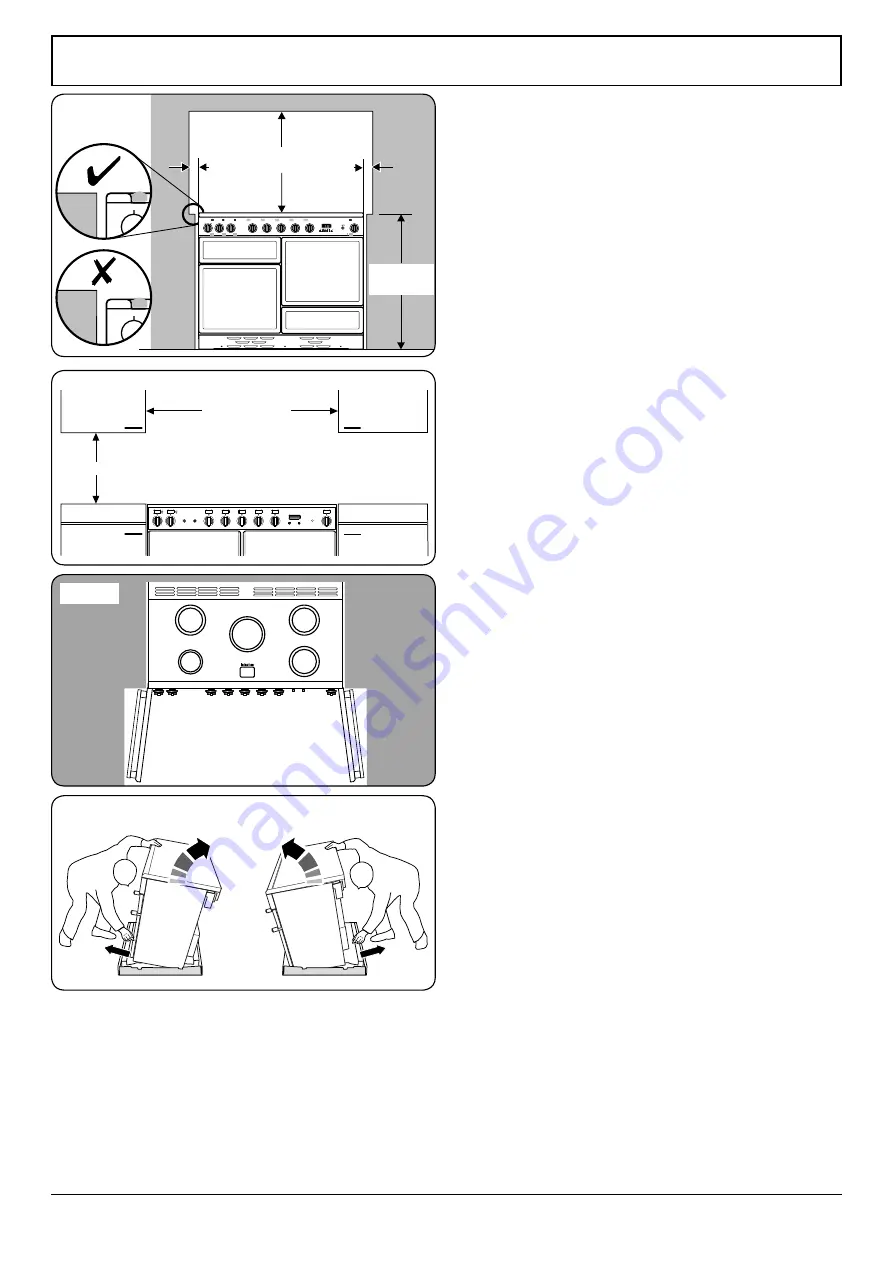

Remove the polystyrene base pack. From the front, tilt the

cooker forward and remove the front half of the polystyrene

base

(Fig.8-4)

. Repeat from the back and remove the rear half

of the polystyrene base.

Fig.8-1

Fig.8-3

Fig.8-2

ArtNo.090-0028 - 90 cooker min spacing GENERIC

ºC

M

ºC

75 mm

min

75 mm

min

650 mm

min

905 mm min

930 mm max

ArtNo.110-0016 110 induction min positions above cooker

410 mm min

1110 mm min*

**

Fig.8-4