INSTALLATION

Check the appliance is electrically safe when you have finished.

27

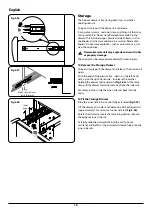

Lowering the Two Rear Rollers

To adjust the height of the rear of the cooker, first fit a 13 mm

spanner or socket wrench onto the hexagonal adjusting

nut

(Fig.8-5)

. Rotate the nut – clockwise to raise – counter-

clockwise to lower.

Make 10 complete (360°) turns clockwise.

Make sure you lower BOTH REAR ROLLERS.

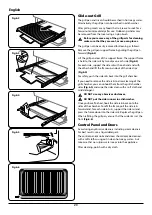

Completing the Move

Unfold the rear edge of the pack base tray. Open the grill

door and right-hand oven door so that you can get a good

grip on the bottom of the fascia panel as you move the oven

(Fig.8-6)

.

Carefully push the cooker backwards off the pack base.

Remove the pack base tray.

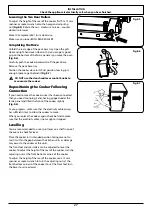

Position the cooker close to its final position, leaving just

enough space to get behind it

(Fig.8-7)

.

n

n

DO NOT use the door handles or control knobs to

manoeuvre the cooker.

Repositioning the Cooker Following

Connection

If you need to move the cooker once it has been connected

then you need to unplug it and, having gripped under the

fascia panel and lifted the front of the cooker slightly

(Fig.8-6)

.

As you progress, make sure that the electricity cable always

has sufficient slack to allow the cooker to move.

When you replace the cooker, again check behind to make

sure that the electricity cable is not caught or trapped.

Levelling

You are recommended to use a spirit level on a shelf in one of

the ovens to check for level.

Place the cooker in its intended position taking care not to

twist it within the gap between the kitchen units as damage

may occur to the cooker or the units.

The front feet and rear rollers can be adjusted to level the

cooker. To adjust the height of the rear of the cooker, turn the

adjusting nuts at the front bottom corners of the cooker.

To adjust the height of the rear of the cooker, use a 13 mm

spanner or socket wrench to turn the adjusting nuts at the

front bottom corners of the cooker. To set the front feet turn

the bases to raise or lower.

ArtNo.010-0004 Moving the cooker

Fig.8-6

Fig.8-5

Fig.8-7