INSTALLATION

Check the appliance is electrically safe and gas sound when you have finished.

22

Retaining

screw

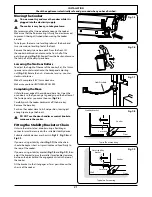

Repositioning the Cooker Following

Connection

If you need to move the cooker once it has been connected

then you need to unplug it and, having gripped under the

fascia panel and lifted the front of the cooker slightly

(Fig.7-7)

, you need to check behind the cooker to make sure

that the gas hose is not caught.

As you progress, make sure that both the electricity cable and

gas hose always have sufficient slack to allow the cooker to

move.

With a stability chain fitted, release it as you ease the cooker out.

Do not forget to refit it when you replace the cooker.

When you replace the cooker, again check behind to make

sure that the electricity cable and gas hose are not caught or

trapped.

Conversion to Another Gas

If the appliance is to be converted to another gas do the

conversion at this point. See the conversion section of these

instructions.

Levelling

You are recommended to use a spirit level on a shelf in one of

the ovens to check for level.

Place the cooker in its intended position taking care not to

twist it within the gap between the kitchen units as damage

may occur to the cooker or the units.

The front feet and rear rollers can be adjusted to level the

cooker.

To adjust the height of the rear of the cooker use a 13 mm

spanner or socket wrench to turn the adjusting nuts at the

front bottom corners of the cooker.

To set the front turn the feet bases to raise or lower.

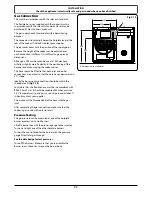

Fitting the Handrail

Using the 2 mm Allen key supplied, loosen the 2 retaining

screws in the base and side of the handrail support. Fit the

handrail support onto the locating bosses on the fascia

(Fig.7-10)

.

Note:

The handle support should face upwards.

Push the support back against the fascia and tighten the

2 retaining screws. Check that each support is secure.

Locate the handrail onto the support tabs. Using the 2.5 mm

Allen key supplied, tighten the 2 retaining screws in the

bottom of each end of the handrail to secure

(Fig.7-11)

.

Retaining screw

Retaining screw

Fig.7-11

Fig.7-10

Summary of Contents for Elise 110 Dual Fuel

Page 1: ...Elise SE 110 Dual Fuel Britain s No 1 Range Cooker USER GUIDE INSTALLATION INSTRUCTIONS ...

Page 4: ...ii ...

Page 33: ...29 Notes ...

Page 34: ...30 Notes ...