17

Control Panel and Doors

Avoid using any abrasive cleaners including cream cleaners.

For best results, use a liquid detergent.

The same cleaner can be used on the doors or alternatively,

using a soft cloth wrung out in clean hot soapy water – but

take care that no surplus water seeps into the appliance.

After cleaning, polish with a dry cloth.

Ovens

Glass Fronted Door Panels

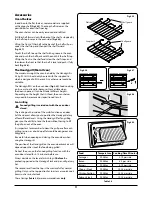

The oven door front panels can be taken off so that the glass

panels can be cleaned. Move the cooker forward to gain

access to the sides (see the

‘Moving the Cooker’

section under

‘Installation’

). Open the oven door slightly and remove the

front panel fixing screws from the door sides, two each side

(

Fig.5.5

)

.Carefully lift off the outer door panel. The inside face

of the glass panels can now be cleaned – take care not to

disturb or wet the door insulation.

Note:

If the door is triple glazed then the inner two panels are

fixed together and should not be separated.

After cleaning, carefully refit the outer door panel and replace

the side fixing screws.

n

n

DO NOT use harsh abrasive cleaners or sharp metal

scrapers to clean the oven door glass since they can

scratch the surface, which may result in shattering of the

glass.

‘Cook & Clean’ Panels

The ovens have side “Cook & Clean” panels which have been

coated with a special enamel that partly cleans itself. This

does not stop all marks on the lining, but helps to reduce

the amount of manual cleaning needed. These panels work

better above 200 °C. If you do most of your cooking below

this temperature, occasionally remove the panels and wipe

with a lint free cloth and hot soapy water. The panels should

then be dried and replaced and the oven heated at 200 °C for

about one hour. This will ensure the “Cook & Clean” panels are

working effectively.

Do not use steel wool, oven cleaning pads, or any other

materials that will scratch the surface.

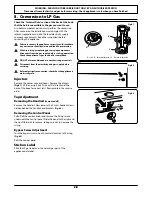

Removing the Oven Linings

Some of the lining panels can be removed for cleaning.

If you wish to clean the enamel interior of the oven, you

will need to remove the shelves before removing the ‘Cook

& Clean’ panels. You do not have to remove the support

brackets to remove the panels. Lift each panel upward and

slide forward off the support brackets

(

Fig.5.6

)

.

Once the panels have been removed, the oven enamel

interior can be cleaned.

Refit in the reverse order.

ArtNo.320-0002b

- Oven door side screws (Toledo)

Fig.5.5

Fig.5.6

Summary of Contents for Toledo XT 110 Dual Fuel

Page 1: ...Britain s No 1 Range Cooker USER GUIDE INSTALLATION INSTRUCTIONS Toledo XT 110 Dual Fuel...

Page 4: ...iv...

Page 36: ...32 Notes...

Page 37: ...33 Notes...

Page 38: ...34 Notes...