16

MOUNTING

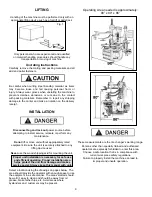

This information must be read and followed carefully to

prevent accidents and injuries during mounting.

1. Inspect the wheel closely for damage. Clean the wheel

and remove any light corrosion or rubber residue. Do not

attempt to service heavily corroded wheels.

(See Fig. 1)

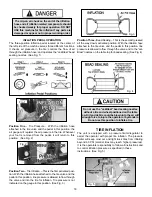

2. Inspect tire for damage, paying close attention to the

beads. Verify size match between tire and wheel.

(See Fig. 2)

3. Lubricate both tire beads liberally with tire manufacturer

approved lubricant. (See Fig. 3)

4. Place tire over wheel and move tower and mount/

demount head into position as described earlier. Position

tire so that the lower bead is above the left “duckbill” side

of the mount/demount head and below the right front knob.

(See Fig. 4)

5. Manually force the tire down into the drop center of the

wheel directly across from the mount head to reduce the

tensional force on the bead. Depress the table top pedal and

rotate the wheel to mount the lower bead. Rotate the table

top until the lower bead is fully mounted. (See Fig. 5-6)

6. For the top bead, rotate the table top until the valve stem

is directly across from the mount head. Lift the upper bead

above the left “duckbill” side of the mount/demount head

and below the right front knob. (See Fig. 7-8)

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Never mount a damaged tire. Never mount a tire

on a rusty or damaged wheel. Damaged tires

and/or wheels may explode.

If you damage the tire bead during mounting,

STOP!, remove the tire and mark it as damaged.

Do not mount a damaged tire.

Fig. 5

Fig. 6

Fig. 7

Fig. 8

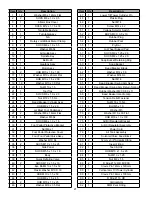

Summary of Contents for R23

Page 25: ...25...

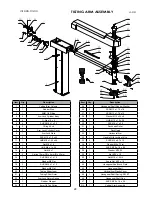

Page 26: ...26 R23 00 00 REVISION A 22 Tire changer...

Page 44: ...44 3 7 3 5 66 0 PL330B 00 00 REVISION A 04...