UPON DELIVERY

1.

Carefully remove all packaging material.

2.

Inspect the equipment and all parts for any signs of concealed shipment or storage damages.

3.

Remember to report any shipping damage to the carrier and make a notion on the delivery receipt.

IMPORTANT SAFETY INSTRUCTIONS

u·

Read all warning labels and the operation man-

ual and be thorough on all aspects of the equip-

ment prior to operations.

·

Always use proper eyeware and hearing pro-

tection when operating this equipment.

·

Before use, on a regular basis check the com-

pressor and all of its components for any dam-

ages and repair or replace all defective or dam-

aged parts.

·

Keep hands and all body parts away from the

equipment at all times (Never operate without

the belt guards).

·

Maintain a clean work area free from spills,

dampness and any other source of contamina-

tion.

·

Make sure this equipment is operated by pro-

fessional personnel only. Keep visitors and

especially children away from work area.

·

Electric shock hazard:

Never use the compressor without connection

to a properly grounded outlet with the specified

voltage and fuse protection.

Do not use the compressor in a wet or explo-

sive environment.

Never attempt maintenance or adjustment with

the power connected or the equipment in oper-

ation.

·

Tank safety valve:

This valve is factory installed to prevent the air

receiver from damage should a malfunction

occur in the compressor pump.

It is factory set a specific limit for your particu-

lar model and adjustment, and should never

be tampered with. Adjustment by user will auto-

matically void the warranty.

·

Pressure switch:

The air pressure switch is set at the factory for

optimum performance of your equipment.

Never bypass or remove this switch, as serious

personal injury or equipment damage could

result from too high pressure.

·

Motor and compressor pump:

Air compressor gets hot while in operation.

Never touch the motor, discharge tubing, or

compressor pump while in operation.

The compressor operates automatically while

the power is connected.

Never attempt any adjustment with power on.

Never operate the compressor with the belt

guard removed.

·

Compressed air caution:

Compressed air from the unit may contain car-

bon monoxide. Air produced is not suitable for

breathing purposes.

Always use a respirator when spraying paint or

chemicals.

Always wear safety glasses or goggles when

spraying air.

·

Air receiver:

Over pressurizing the air receiver could cause

an explosion or rupture. To protect from over

pressurizing, a factory preset safety valve is

included. DO NOT REMOVE, MAKE ADJUST-

MENT OR SUBSTITUTIONS FOR THIS

VALVE.

Occasionally pull the ring on the valve to make sure

that the valve operates freely. If the valve does not

operate freely, it must be replaced. Never weld to, drill

into or change the air receiver in any way.

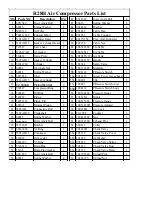

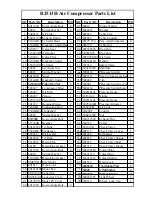

Changing or tampering with any of the above men-

tioned conditions may result in voiding of the manufac-

turer's warranty. Be advised that any replacement parts

should be purchased with the same specifications as

the original equipment. Please contact your authorized

dealer for replacement parts or specifications.