Disconnect air supply to machine.

Add oil to the lubricator if the fluid level is below the

middle of the oil reservoir. Unscrew the Oil Reservoir, add

SAE 10W non-detergent oil or an air tool oil if necessary.

NOTE:

This adjustment will require two persons to perform.

1. With the Air source connected, depress the Bead

Breaker Pedal to operate the Bead Breaker.

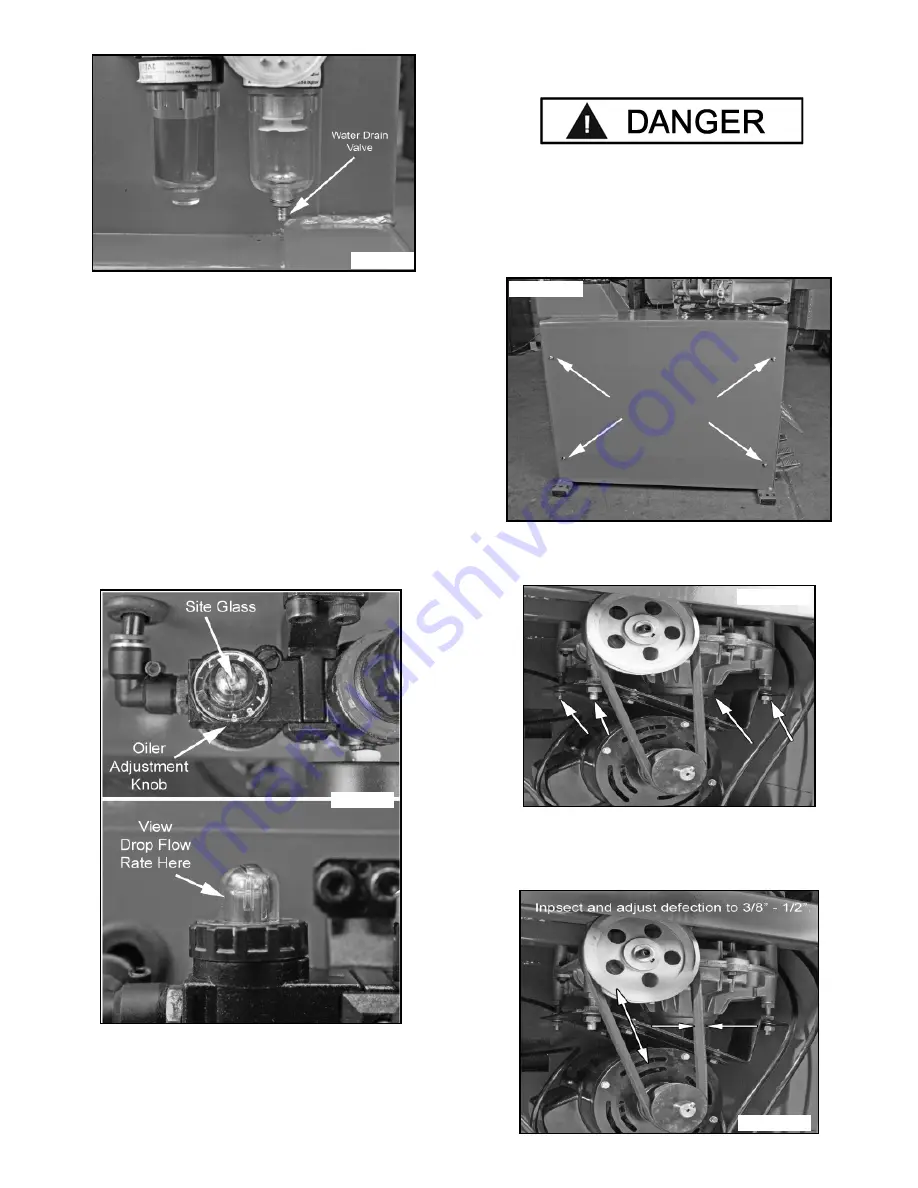

2. Observe the site glass and adjust the oil flow of the

oiler by turning the Oiler Adjustment Knob so that 2-3

drops of oil drip through the site glass for each operation

of the Bead Breaker Pedal. (See Fig 17.6)

(Either reservoir may be removed for cleaning by turning

the reservoir counter-clockwise and pulling down.)

3. Reconnect the air supply when service/adjustments are

complete.

Turntable Drive Belt Inspection / Adjustment.

DANGER!

The motor on this machine contains high

voltage. Disconnect power at the receptacle before

performing any electrical repairs. Secure plug so that it

cannot be accidentally plugged in during service.

1. Remove the Side Panel. (See Fig. 17.12)

2. Loosen the four Motor mounting / adjusting bolts and

nuts. (See Fig. 17.13)

3. Inspect the Drive Belt for cracking and wear and

replace as necessary. Adjust the Belt deflection to

3/8” - 1/2”. (See Fig. 17.14)

30

Fig. 17.5

Fig. 17.6

Fig. 17.12

Fig. 17.13

Fig. 17.14

Summary of Contents for R715

Page 32: ...32...

Page 33: ...33 RECORD ALL MAINTENANCE NOTES AND SERVICE HISTORY HERE...

Page 34: ...34 5 7 5 1 5...