INSTALLATION

1. Assemble the bench and chip trays according to the

diagram on page

7

. Tighten all fasteners securely.

2. After assembly, the bench should be leveled. The bench

may be bolted down with 3/8” concrete bolts or lag screws.

3. Unbolt the lathe from the shipping pallet and remove

any packing materials and protective wrapping. Lift the

lathe onto the bench.

Always follow safe lifting practices when lifting heavy loads.

Use a forklift or crane only. Do not attempt to lift lathe unit

onto the bench without the use of material handling

equipment with a lifting capacity 400 pounds or greater.

4. Bolt the lathe to the bench with the hardware provided.

Tighten fasteners securely.

5. Remove any packing materials and protective wrapping

from the lathe and components.

6. Make sure the lathe is turned off. Plug lathe into a properly

installed and grounded outlet that matches the lathe plug.

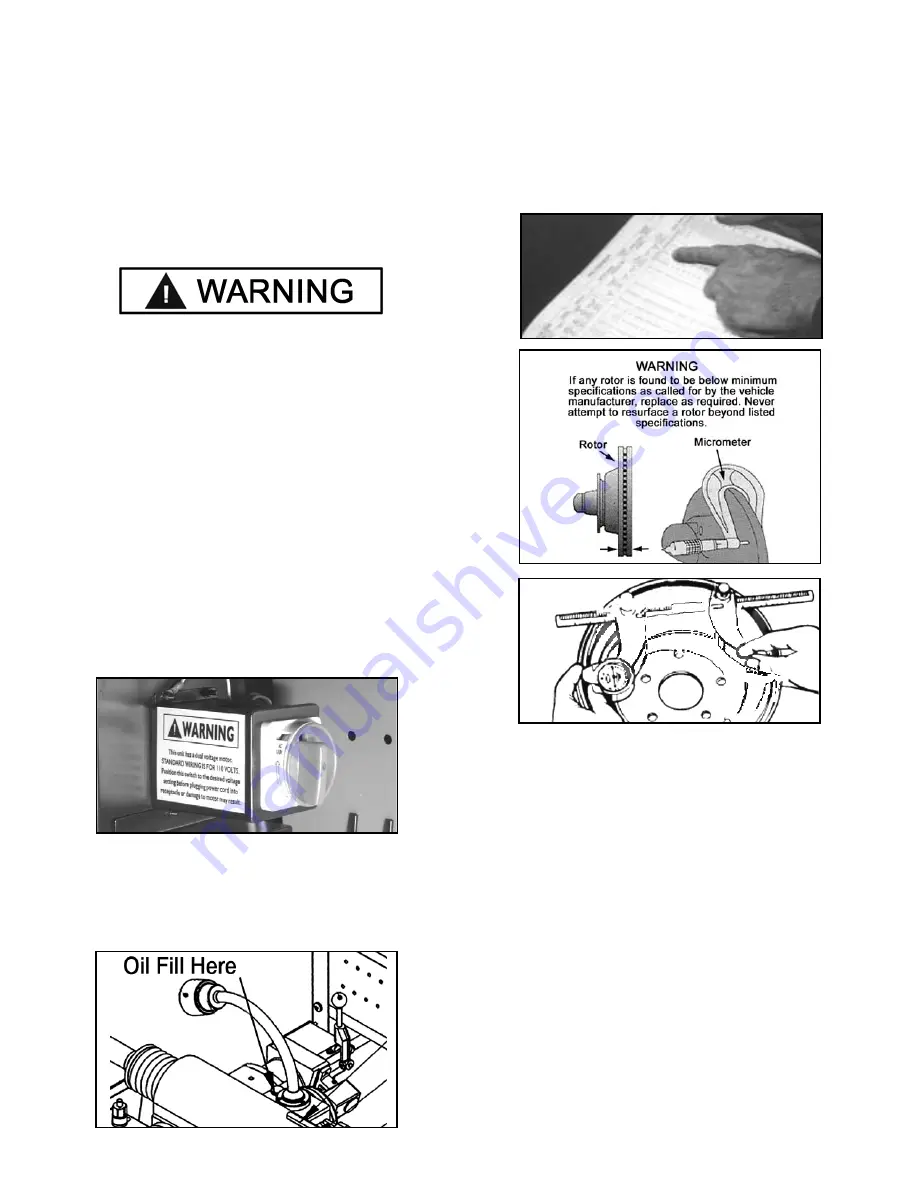

IMPORTANT NOTE

Position the voltage selector switch at the rear of the unit to

the appropriate voltage setting before plugging the lathe into

outlet. Verify that the lathe plug and grounding-type

receptacle match.

7. Remove the oil plug, insert the oil dipstick, and check oil

level. The lathe is shipped with the correct amount and

type of oil. Add oil as necessary to reach the correct mark

on the dipstick. Use only EP-80-90 gear oil. Oil level

should be checked often.

BRAKE ROTOR/DRUM INSPECTION

1. Before attempting any resurfacing, rotor and/or drum

inspection is necessary. Determine the manufacturer's

specifications from an approved specification guide.

2. Using a digital micrometer or other measuring tool, record

the thickness of the rotor or drum. Observe any deep scores

and gouges. This depth will also need to be recorded.

3. Determine if the total amount of material to be removed

will meet the manufacturer's minimum specifications. If any

rotor is found to be below minimum specifications as called

for by the vehicle manufacturer, replace as required.

BASIC OPERATION

To help you understand drum and rotor turning, read the

following that helps explain the features, operation and

principles of drum and rotor resurfacing.

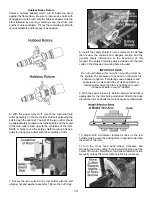

Horizontal Spindle / Arbor

The spindle (horizontal main shaft) is motor driven and

turns the arbor (main rod with threaded tip) which the brake

drums or rotors are mounted on. When turning the drum or

rotor via the arbor and holding a cutting tool against the

braking surface, metal can be removed making the final

result a smooth finish that meets original factory

specifications. Smooth brake surfaces will extend the life of

the brake pads and increase brake operation efficiency.

8