13

SECTION 7

AIR SOURCE

This model requires a 14 to 15 CFM air source at

45-165 PSI minimum pressure. The safe operating pressure

range for this model is between 140 PSI and 165 PSI at the

machine.

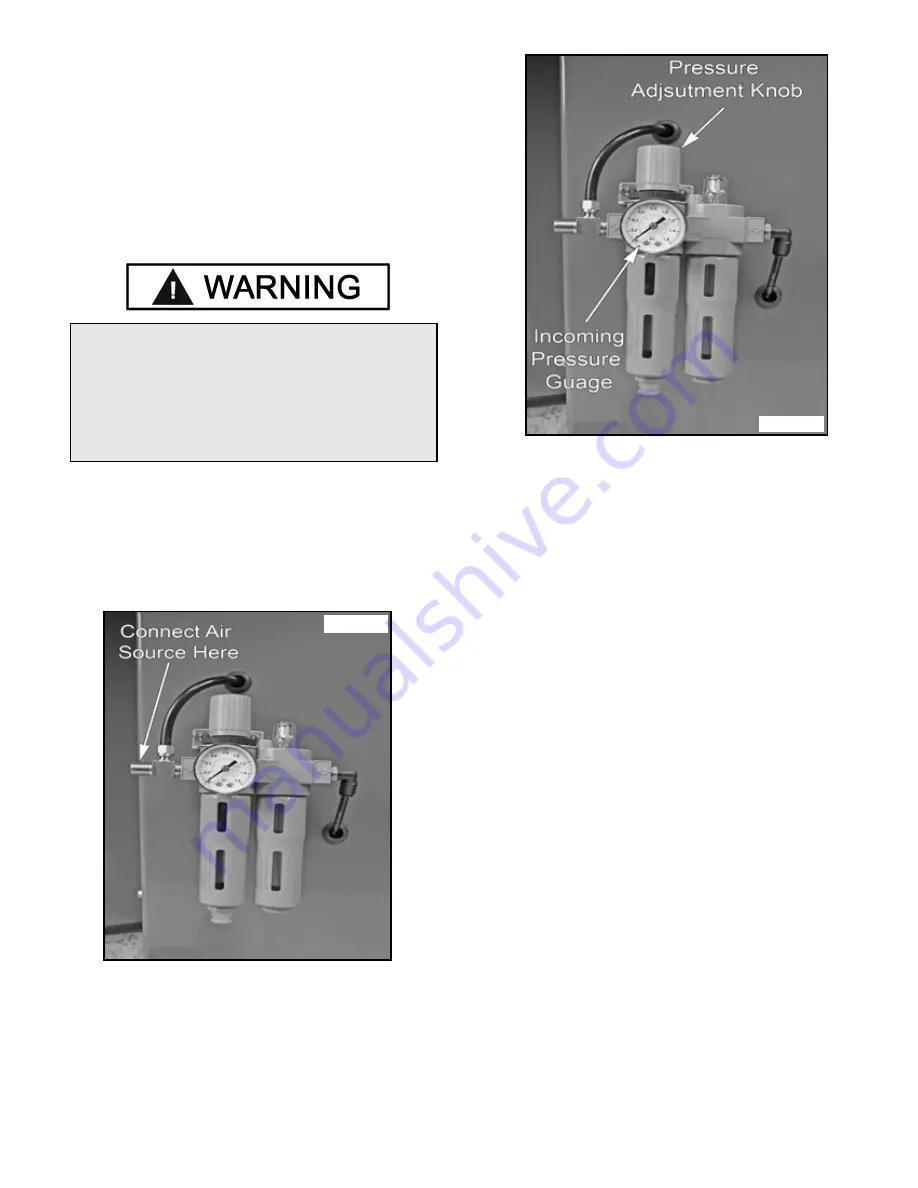

1. Connect the Air Supply to the Air Oil Regulator. The unit

is furnished with a 1/4” pipe thread female fitting for easy

connection. This connection is located on the right side of

the rear of the machine. A 1/4” ID hose (or pipe) for

connection to the machine is satisfactory. Sufficient air

pressure assures good performance. (See Fig. 7.1)

2. Adjust Pressure by turning knob at the top of the Air

Regulator and reading the Pressure on the Gauge at the top

of the Air Tank/Tower. (See Fig. 7.2)

3. Drain water, fill oil and adjust the flow of oil as shown on

page 27.

Fig. 7.1

Fig. 7.2

WARNING!

CHECK THAT THE TURBO-BLAST VALVE IS

CLOSED BEFORE CONNECTING ANY AIR

SOURCE. IF VALVE IS OPEN, AIR BLAST OR

HOSE MOVEMENT MAY DAMAGE PERSONNEL

OF MACHINE.

Summary of Contents for RX3040

Page 29: ...29 Fig 9 47 Fig 9 48...

Page 58: ...58 CRITICAL SAFETY WARNINGS...

Page 59: ...59 CRITICAL SAFETY WARNINGS...

Page 61: ...61 Parts Breakdowns...

Page 62: ...62...

Page 63: ...63...

Page 64: ...64...

Page 65: ...65...

Page 66: ...66...

Page 67: ...67...

Page 68: ...68...

Page 69: ...69...

Page 70: ...70 T I R E C H A N G E R X Electric Schematic Diagrams 12...

Page 71: ...71 T I R E C H A N G E R All electric appliances must be installed by electricians 13...