12

BALANCING INSTRUCTIONS

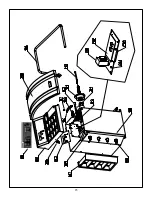

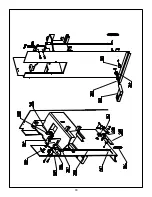

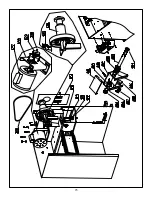

1. First determine which mounting method you will use for

the wheel.

2. Select a centering / mounting cone that best fits the

center hole of the wheel.

3. After installing the necessary mounting hardware, lift the

wheel onto the threaded shaft and slide it back against the

arbor hub. It will be necessary to lift the wheel slightly when

positioning the cone in the center of the wheel hole.

CAUTION!

DAMAGE CAUSED BY STRIKING OR HITTING THE

QUICK-NUT WITH HAMMER, TIRE IRON OR HEAVY

OBJECT IS NOT COVERED UNDER WARRANTY!

4. While holding the wheel and hardware in position, thread

the Quick-Nut over the arbor and secure tightly.

Never hammer or hit the Quick-Nut to tighten.

WARNING!

Always make sure that the Quick-Nut engages the arbor

threads by at least four (4) full turns. It helps to spin the

wheel while at the same time tightening the Quick-Nut.

Never exceed weight capacity of balancer!

Never hammer or strike the Quick-Nut to tighten.

CAUTION!

DAMAGE CAUSED BY STRIKING OR HITTING THE

QUICK-NUT WITH HAMMER, TIRE IRON OR HEAVY

OBJECT IS NOT COVERED UNDER WARRANTY!

WARNING!

Do not attempt to balance wheels that are larger

than the machine was designed for.

Inputting Wheel Data

Prior to balancing any wheel, specific data relating to that

particular wheel must be entered into the computer. If the

data displayed on the screen does not match that of the

wheel you are attempting to balance then the wheel will not

be accurately balanced. The three data requirements are;

“-A-” Offset, “-L-” Width and “-d-” Diameter.

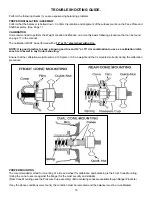

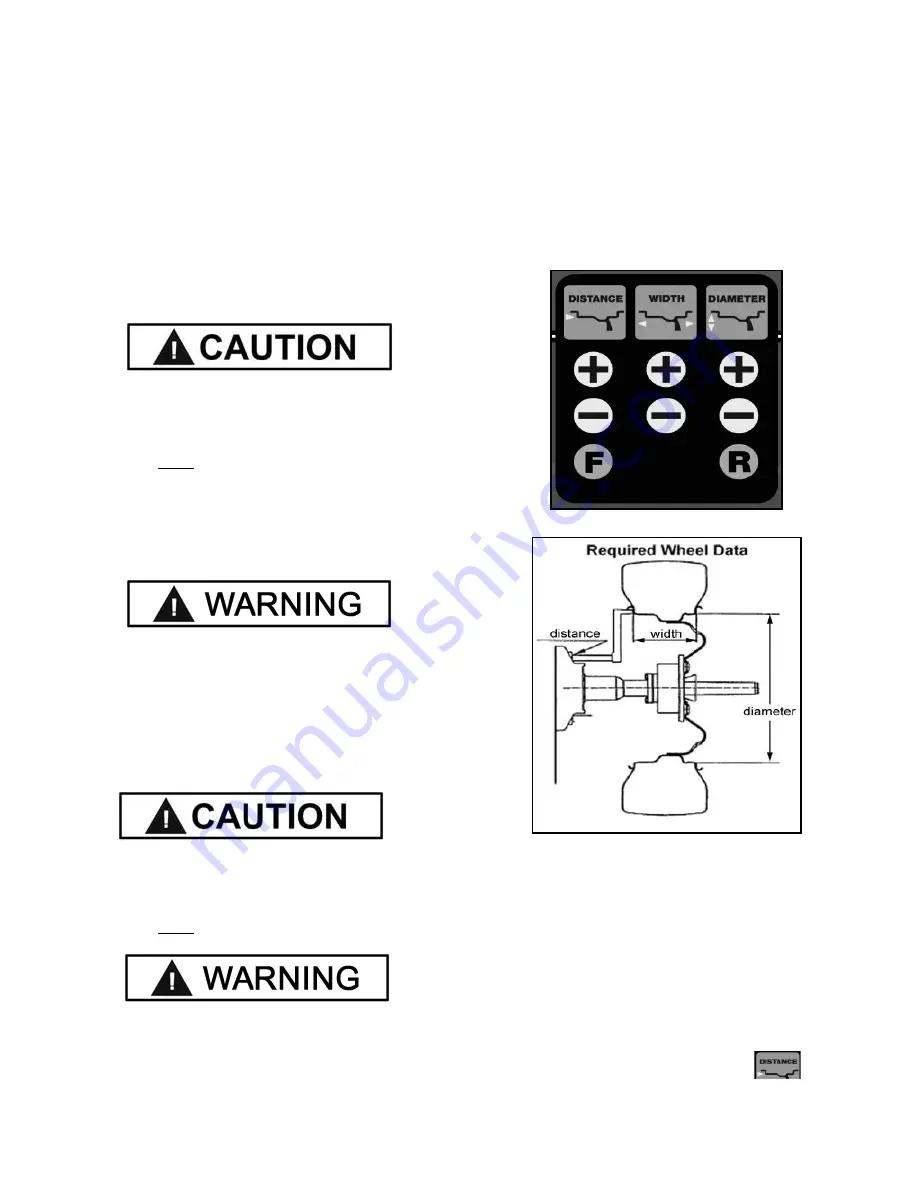

WHEEL DATA KEY BOARD

dis - Wheel Offset

This is the distance between the side of the balancer and

the inner edge of the wheel. To enter Wheel Offset data

refer to the instructions below.

1. Turn the machine on.

2. Press the

+

or

-

button below Distance .

3. -

A-

will be displayed in the INNER window.