R80EX Tire Changer

20

P/N 5900087 — Rev. B — Jan. 2020

Go in straight; do not let the drill wobble. Use a carbide-tipped drill bit (conforming to ANSI

B212.15).

3.

Thoroughly clean each hole.

BendPak Ranger recommends using a wire brush and a vacuum to get the hole very clean.

Do

not

ream the hole. Do

not

make the hole any wider than the drill bit made it.

4.

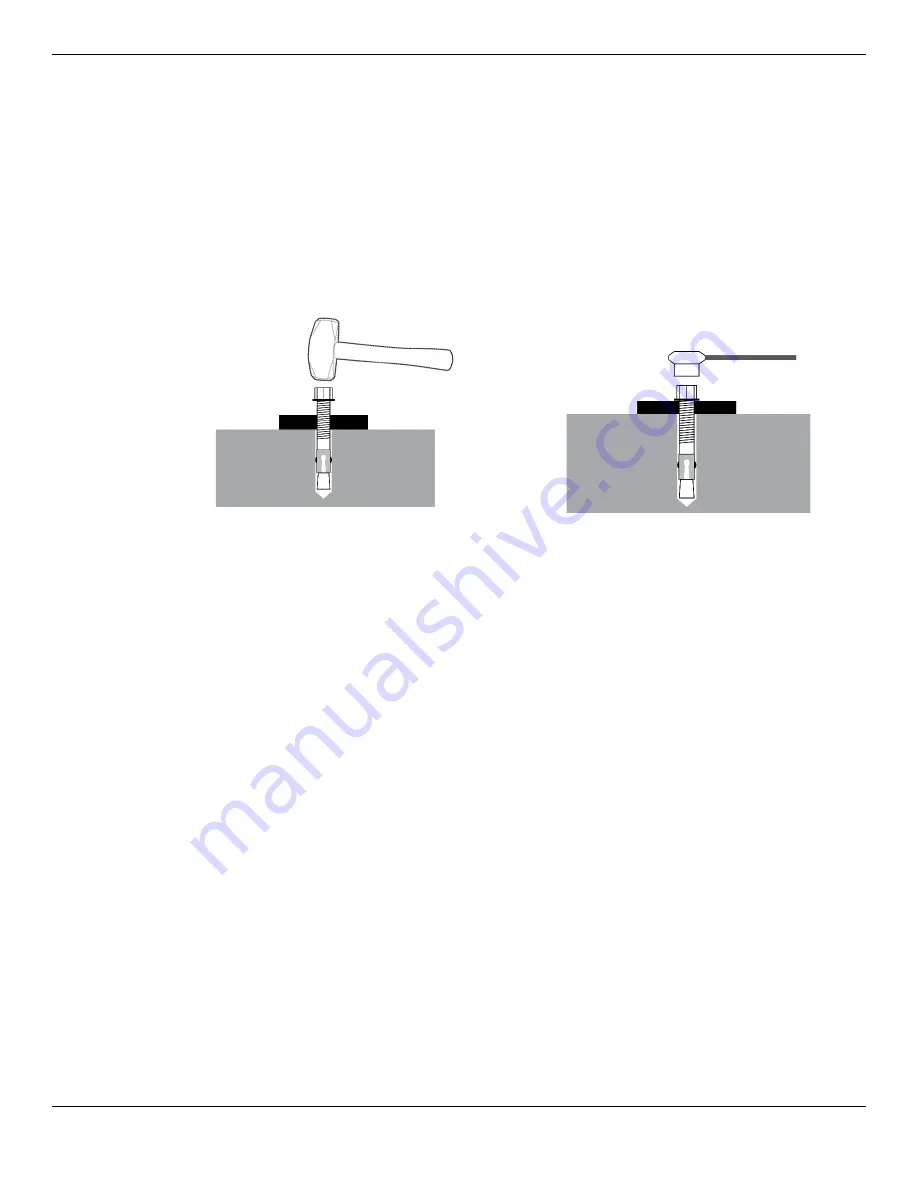

Make sure the Washer and Nut are in place, then insert the Anchor Bolt into the hole.

The Expansion Sleeve of the Anchor Bolt may prevent the Anchor Bolt from passing through the

hole in the base of the Tire Changer; this is normal. Use a hammer or mallet to get the Expansion

Sleeve through the base and down into the hole.

Even using a hammer or mallet, the Anchor Bolt should only go into the hole part of the way; this is

normal. If the Anchor Bolt goes all the way in with little or no resistance, the hole is too wide.

Once past the hole in the base, the Anchor Bolt eventually stops going down into the hole as the

Expansion Sleeve contacts the sides of the hole; this is normal.

5.

Hammer or mallet the Anchor Bolt the rest of the way down into the hole.

Stop when the Washer is snug against the base of the Tire Changer.

6.

Use a torque wrench to tighten each Nut

clockwise

to the torque recommended by the

manufacturer of the Anchor Bolt.

If no torque is specified, BendPak Ranger recommends ~55 lbf-ft / 74 N-m for a 3/8 in diameter

Anchor Bolt.

Important

:

Do

not

use an

impact

wrench to torque the Anchor Bolts.

Wrenching the Nut forces the Wedge up, forcing out the Expansion Sleeve and pressing it tightly

against the Concrete.