4

3. Let go of the release pedal; the air in the oil system

should be bled successfully. If not successful, repeat

procedure but first check oil level, or see procedures

under maintenance section, steps 2 through 5.

OPERATING INSTRUCTIONS

1. Follow the vehicle’s recommended service procedure

for removal of the component.

2. Position the jack under the vehicle.

3. Raise the jack by operating the foot pump until the

saddle touches the component.

4. Adjust the support brackets to fit the component.

5. Use the tilt crank to align the saddle with the

component.

6. Finish raising the jack to the component. Secure the

chain assembly around the component.

MAINTENANCE

1. Regularly lubricate all moving parts of the jack. Pay

special attention to the lift screw and related linkages.

A medium weight lubricating grease should be used

on all external moving parts, such as the bearing

surface, pivot points, tilt screws, etc.

2. Regularly check the oil level. With the saddle fully

lowered, remove the oil seal screw, and check the

oil level. The oil level should be at the bottom of the

screw hole. Add oil if necessary.

3. Use only hydraulic jack oil. Do not use hydraulic

brake fluid.

4. If the jack fails to operate, check the oil level and/or

bleed unit before seeking service.

5. Do not use this jack as a wash rack when washing or

steam cleaning transmissions.

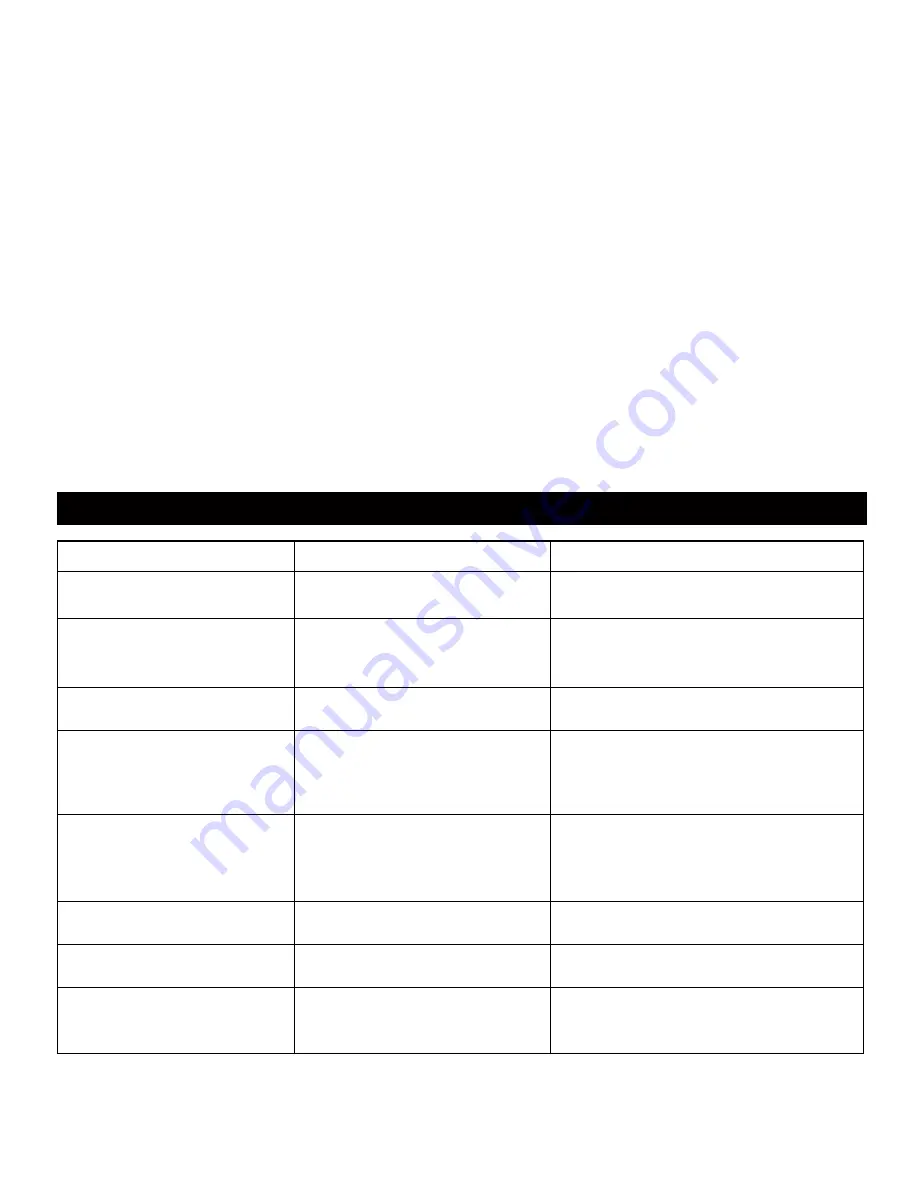

TROUBLESHOOTING GUIDE

Trouble

Cause

Solution

Unit fails to extend or extends

partially

1. Low fluid level

1. Refer to Maintenance section and fill to

correct fluid level.

Incomplete or spongy cylinder

response when foot pedal is

pumped

1. Low fluid level

2. Air in system

1. Fill to correct fluid level.

2. Refer to Bleeding Air from the Hydraulic

System.

Abnormal leakage through unit

breather

1. Low fluid level

1. Refer to Maintenance section and fill to

correct fluid level.

Unit fails to extend when foot

pedal is pumped

1. Release valve malfunction

2. Contamination

3. Cylinder packing failure

1. Pump foot pedal with release valve open.

2. Disassemble and clean unit.

3. Install the necessary items from the seal

kit.

Cylinder creeps

1. Load exceeds maximum lifting

capacity

2. Release valve is leaking

1. Reduce load or use jack with sufficient

lifting capacity.

2. Flush release valve by pumping foot pedal

with release valve open.

Cylinder doesn’t retract when

release pedal is activated

1. Light load

2. Cylinder is binding

1. Unit requires 35 lbs. to return.

2. Disassemble unit; replace defective parts.

Cylinder doesn’t extend

1. Contamination

2. Bad packing

1. Disassemble and clean unit.

2. Install new seal kit.

Cylinder extends when foot pedal

is pressed, and retracts as foot

pedal retracts

1. Release valve malfunction

2. Contamination

1. Flush release valve by pumping foot pedal

with release valve open.

2. Disassemble and clean unit.

Summary of Contents for RTJ-1

Page 5: ...5 PARTS BREAKDOWN ...

Page 8: ...8 ...