11 of 48

20180521-Ver1

MAINTENANCE GUIDE

Before cleaning the grill, place it in an area clear and free from combustible materials,

gasoline and other flammable vapors and liquids.

Do not obstruct the flow of combustion and ventilation air.

GREASE TRAY

The grease tray should be emptied and wiped down periodically and washed with a mild

detergent and warm water solution. A small amount of sand or cat litter may be placed in

the bo

ttom of grease tray to absorb the grease. Check the grease tray frequently. Don’t

allow excess grease to accumulate in the grease tray. Accumulated grease will easily ignite.

Therefore, it is important to clean and remove grease after each use.

GRILL BURNERS

Extreme care should be taken when removing a burner as it must be correctly centered on

the orifice before any attempt is made to re-light the grill. Frequency of cleaning will depend

on how often you use the grill.

Spiders and small insects occasionally spin webs or make nests in the grill burner tubes

during transit and warehousing. These webs can lead to gas flow obstruction which could

result in a fire in and around burner tubes. This type of fire is known as flashback and can

cause serious damage to your grill and create an unsafe operating condition for the user.

Although an obstructed burner tube is not the only cause of flashback, it is the most

common cause. To reduce the chance of flashback, you must clean the burner tubes

before assembling your grill, and at least once a month in late summer or early fall when

spiders are most active. Also, perform this burner tube cleaning procedure if your grill has

not been used for an extended period of time.

You should inspect the burners at least once a year or immediately after any of the

following conditions occur:

1. The smell of gas in conjunction with the burner flames appearing yellow.

2. The grill does not reach temperature.

3. The grill heats unevenly.

4. The burners make popping noises.

WARNING

ENSURE that the gas supply and the knobs are in the “OFF” position.

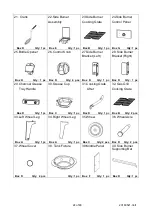

Cleaning The Burner Tubes and Burner Ports (For

main burners)

To reduce the chance of

FLASHBACK FIRE

you

must clean the Burner Tubes as follows at least once

a month in summer and fall or whenever spiders are

active in your area, and if your grill has not been used

for an extended period of time.